Screw sand washer

1. Introduction

Sand screw washer is used primarily to process crushed stone and gravel, with the range from 3mm up to 100mm, it effectively removes clay, dirt, dust and coatings of the crushed stone and gravel, which can not be removed by wet screening alone.

By screw washer cleaning and classifying refers to removing water soluble clay, silt, and micro sized fine sand particles typically less than 150 mesh in size.

Hydraulic separation uses water as the medium to clean and classify sand particles by weight. Larger particles weigh more than smaller particles so the larger particles sink and are collected in the bottom of the trough.

The sand particles are transported to the inclined discharge end by a double pitched steel spiral shaft equipped with replaceable polyurethane wear shoes. The smaller lighter unwanted particles are floated to the surface of the claim settling pool and are discharged over the weirs.

2. Features of sand screw washer

-Polyurethane replaceable wear shoes cover the full face of spiral

-Optional Ductile Iron QT400 wear shoes available

-Outboard grease lubrication, protects bearing from external water and dirt

-Self-aligning spherical roller bearing assemblies

-Easy inspection and fast maintenance

-Heavy duty chain and cycloidal pinwheel gearbox transmission

3. Technical data of sand screw washer 2XL760

Model: 2XL760

Motor: 7.5kw x 2

Screw diameter: 760mm

Rotation speed: 17 RPM

Process capacity: 30 to 80 tons per hour

Weight: 6800 KG by polyurethane plates

4. Production procedure

A. Welding of the hull

B. Shaft and bearings assembly, original LYC bearings

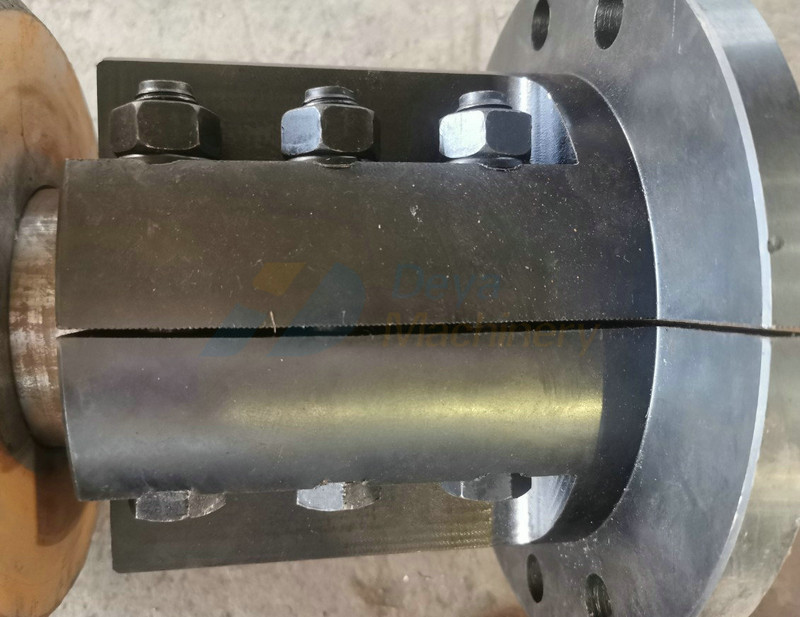

C. Unique seal of the shaft

D. Installation of bearings, joints, main shafts

E. Welding screws & overflow weir of the sand screw washer

F. Polishing, coat painting & surface painting

G. Installation of the polyurethane plates, anti-loosening and anti-retraction bolts

H. Installation of motor & heavy duty chain

I. Installation of shaft press plate, grease spout, safety cover, data plate

Deya machinery team puts heart and soul for each equipment supplied. Qualified equipment create much more value than expected, your trust values much more than quality and service. Contact us for more information if you are interested in the sand screw washer.