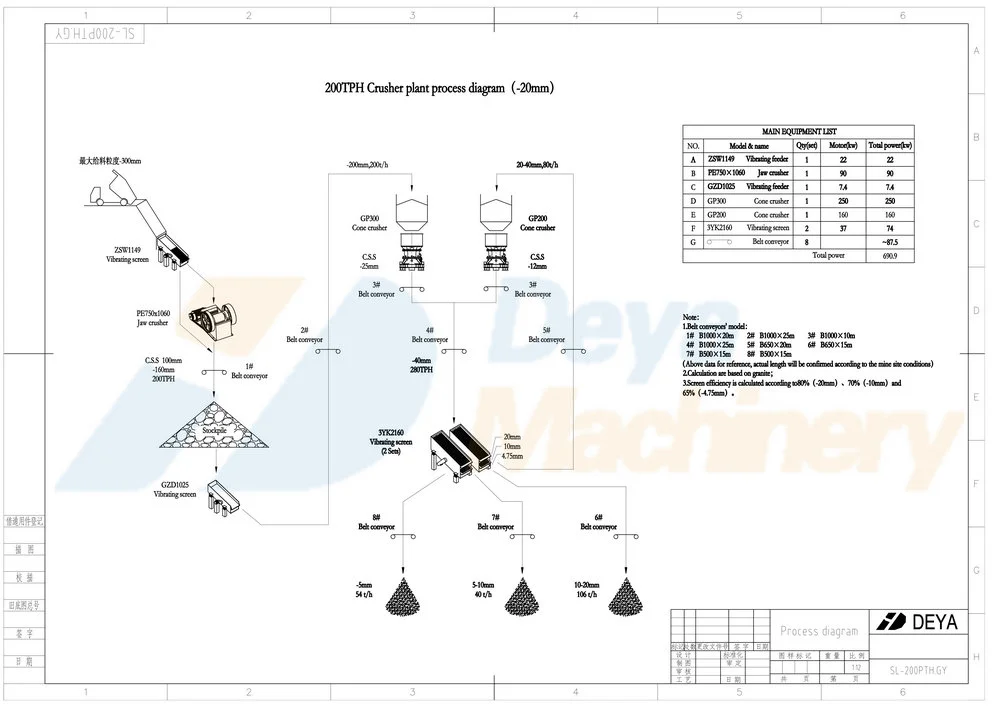

200 TPH stone crushing plant

Introduction

The stone crushing plant is for complete production line such as limestone, granite, river stone, basalt and so on to product aggregates for ready mix concrete, building material, construction site and others.

Stone crushing plants can be equipped with gyratory crushers, jaw crushers, impact crusher or cone crusher depending on material properties and required capacities.

Deya Machinery is able to provide mobile, modular, or stationary stone crushing plants and work together with our clients to choose the most suitable machine type depending on the mineral deposit, mine plan and mining method.

• Plant location, Henan, China, 180KM to Deya Machinery's company

• Designing capacity: minimum 200 tons per hour

• Required size: all less than 20mm

Factors to consider for designing

The principal design parameters that drive stone crushing plant selection and configuration include the following

• Capital cost

• Stone characteristics

• Safety and environment

• Project location

• Life of mine/expansion plans

• Production requirements

• Operational considerations

• Maintenance requirements

Key equipment list

• Bridge wall

• Primary hopper

• Grizzly feeder

• Primary jaw crusher

• Secondary crushing by single cylinder cone crusher GP300

• Tertiary crushing by single cylinder cone crusher GP200

• Vibration screen 3YK2160

• Belt conveyors

Equipment in details

1. Bridge wall

It provides rigidity to travel stone ground level to hopper level. Fully mobile crushing plants are directly fed by shovel or wheel loader and no haulage trucks are required.

2. Primary hopper

It is for materials loading via the bridge wall. Typically are installed by height difference in the working site.

The hopper can be designed and produced in Deya Machinery’s workshop, while delivered by pieces, and assemble in the working site by screws and bolts, only need a little work for welding in the working site, for the reinforcement of the hopper.

3. Grizzly feeder

Recommend model: ZSW4911, key parameters as follows

• Feeder size: 4900x1100

• Max feed size: 630 mm

• Capacity: 150 to 320 TPH

• Motor: 15 KW

• Weight: about 6647 KG

• Frame: heavy duty, steel plate in welded construction

• Drive by V belts and electrical motor

• Lubrication: gear oil under the feeder

Features: heavy duty vibrating grizzly feeder is provided with grizzly bars on top & wire mess aperture deck at bottom for positive scalping of quarry rejects before primary crusher.

4. Primary jaw crusher

Recommend model PE750x1060, or PEV 750x1060

• C.S.S. (closed side setting) size: 100mm

• Type: Heavy duty single toggle jaw crusher

• Feed opening: 750x1060mm

• Max feed size: 630 mm

• Discharge range: 80 to 140mm

• Capacity: 110 to 320 TPH

• Main shaft rotation speed: 250rpm

• Motor: 110 KW

• Weight: about 29 tons

• Swing jaw: Heavy duty steel casting

• Jaw plates: ZGMn13Cr2 and ZGMn18Cr2, High manganese steel casting

• Eccentric shaft: Heavy duty, carbon steel forging shaft with heat treatment

• Bearings: Heavy duty, self aligning spherical roller bearings

• Lubrication : Grease lubricated

• Drive: Through v-belts

• Type of starter : Soft starting by control panel

• Spherical roller bearings

• Lubrication : Grease lubricated immersed lubrication

5. Stockpile

In order to improve the operation rate of large scale stone crushing plant, intermediate stockpile is often set up between the initial crushing stage and the secondary crushing stage, which can store a considerable amount of materials and divide the whole system into two sections.

Advantages of intermediate stockpile as follows:

1. When the front section equipment cannot operate normally due to mine reasons, transportation reasons or maintenance equipment, etc., the back section equipment can operate normally for several hours or even days by relying on the stock material in the intermediate stockpile.

2. It can also be separated from the operating time, usually the initial crushing stage has larger capacity due to the larger feeding size, production time does not have to be too long to meet the daily output, while subsequent equipment does not have to be configured too large, it can increase the daily operation time, so that the existence of the intermediate stockpile has the potential to make the front and rear section using different operating hours.

Intermediate material stockpile has various structural forms, the common form is to use the surface pile material, excavate the underground channel, and use feeder and belt conveyor to convey the material out from underground. Restricted by terrain, investment, etc., it is generally more appropriate to store 1~2 days of production.

6. Single cylinder cone crusher GP300 and GP200

• Type: Hydraulic cone crusher

• Feed opening: 300 mm

• Main body: Heavy duty, cast steel

• Mantle concave: High manganese steel casting, zgmn18cr2

• Eccentric shaft: Heavy duty carbon steel with heat treatment

• Bearings: Heavy duty, self aligning spherical roller bearings

• Lubrication: Thin oil lubrication, automatic oil lubrication for main bearings, counter shaft bearings gear pinion.

• C.S.S. Adjustment: Hydraulic power pack with push button control

• Drive: Through v-belts

• Motor: 250kw for gp300, and 160kw for gp200

7. Vibrating screen 3YK2160 two sets

• Number of layer: 3

• Mesh size: 4.75mm, 10mm, 20mm

• Feed size: Less than 300mm

• Capacity: 150 to 260 tons per hour

• Type : Heavy duty inclined circular motion screeen

• Size : 2100mm wide x 6000 mm long

• Number of layer: Three layers

• Frame : Heavy duty, steel plate in welded construction

• Eccentric shaft : Heavy duty, carbon steel with heat treatment

• Bearings : Heavy duty, self aligning spherical roller bearings

• Lubrication : Greas lubricated immersed lubrication

• Drive: Through direct connection of soft belts

• Motor : 37 kw per set

8. Belt conveyors

• Width 500mm, 650mm, 1000mm.

• Belt speed range: 1.2m/s, 1.4 m/s or 1.8 m/s

• Carry idler diameter: 89mm

• Return idler diameter: 89mm

• Power range: 3KW to 30KW

• Head drum diameter: 340mm, or 422mm or 524mm

Maintenance requirements

• Crusher wear parts

• Screen decks

• Feeder wear parts

• Conveyor skirting and adjustment

• Oil and lubrication

• Conveyor belt repair

• Visual inspections

• Electrical and instrumentation adjustments

Contact us to visit this plant and customize stone crushing plant for you.