Introduction

It is unavoidable that over time, wear parts will need to be replaced. With decades of rich experience, feedback from clients, and keep learning knowledge, Deya Machinery certified wear parts are of the highest quality and are designed to maximize the jaw crusher productivity.

Austenitic manganese steel is the industry standard material for jaw crusher liners. Due to its ability to work-harden during operation, it has proven to be versatile, and works well in a majority of applications. Typical material ZGMn13Cr2 and ZGMn18Cr2.

Jaw plates benefits

• Increases machine uptime

• Reduces the number of changes required for the jaw plates

• Improves cost per tonne

• Primarily designed to work with the quarry tooth liner

• Field testing has seen an increase in wear life of over 30%

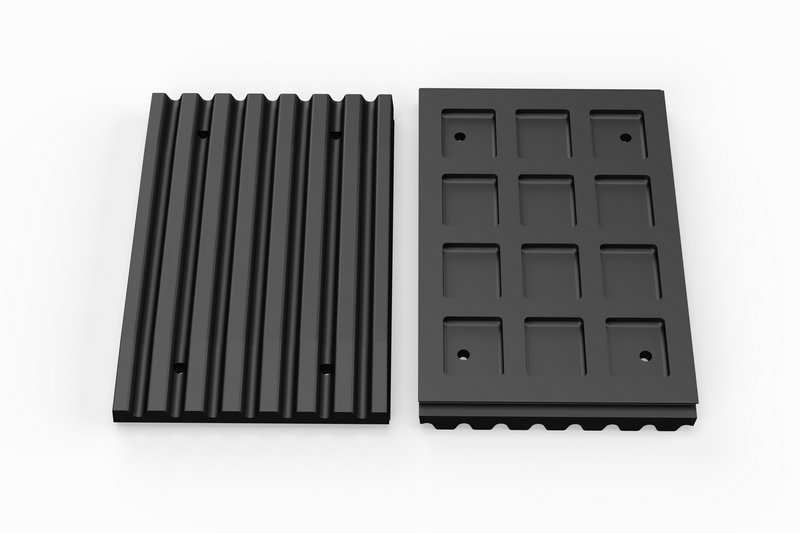

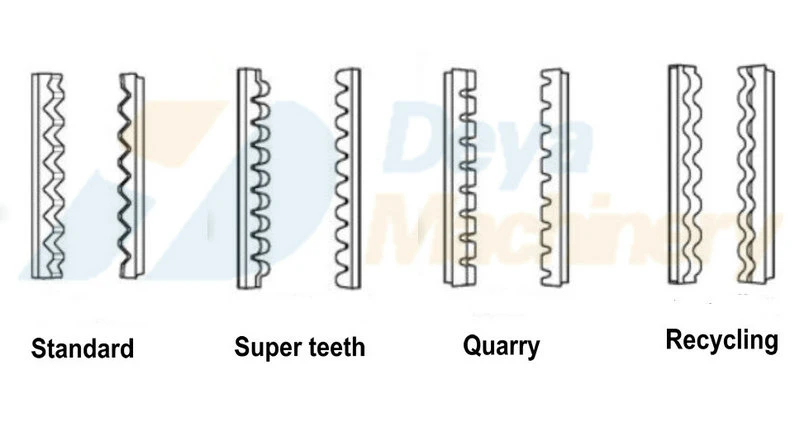

Types of jaw plates

Due to the wide range of applications and feed material, many types of jaw plates are available for Deya Machinery’s jaw crushers. To name a few of them

Standard

• Good in gravel and non abrasive rock

• Tooth spacing ideal for fines removal

• Power requirement and crushing stresses are in balance

• Less slabby product

• Reduced lifetime in abrasive application

Super teeth

• General use in gravel and blasted rock

• Tooth spacing ideal for fines removal

• More tooth contact surface area compared to standard profile

• More wearable Mn-steel than in standard jaws

• Power requirement and crushing stresses are in balance

• Less slabby product

Quarry

• Good in abrasive and/ or blasted rock

• Flat tooth profile maximizes lifetime (more surface area to crush with)

• More wearable Mn-steel than in standard jaws

• Higher stresses and power requirements

• Less space for fines to pass through (fines removal from feed material is important)

• Increase in slabby product

Recycling

• Ideal for concrete, brick etc., demolitionwaste

• Wear and crushing forces in good balance

• Tooth spacing ideal for fines removal

Factors affect the wear of jaw plates

There are several different factors affect the wear of wear parts, a few of them as follows

•Type of wear, typically abrasive

•Environmental factors, like moisture

•Crusher operating parameters, C.S.S., cavity

•Feed material, distribution, rock type, feed size

•Wear material itself, chemical composition, casting process, heat treatment, etc.

Critical steps to produce qualified jaw plates

Below are a few critical steps to producing high quality jaw plates:

1. Raw material selection, it is important to get the right raw materials, and make sure the ratio of each metal is correct. Raw materials should be carefully selected for melting in order to get the material analysis inside strict specifications and to reduce the amount of certain impurities.

2. Temperature control, during melting and pouring the temperatures are carefully controlled in order to achieve fine grain structure for the castings.

At the same time samples are taken to verify the material analysis and adjust if necessary.

Melted metal is then poured into sand molds (or by Lost-foam) where the metal slowly solidifies. The molds have carefully designed feeding and gating channels to ensure solid castings.

3. Heat treatment, it is another critical step to producing ductile high quality castings. Temperature, time and quenching need to be well controlled in order to avoid grain boundary carbide formation.

4. Machining, after the heat treatment has been completed, castings are machined according to strict tolerance to ensure a perfect fit to the crusher.