Introduction of double roll crusher

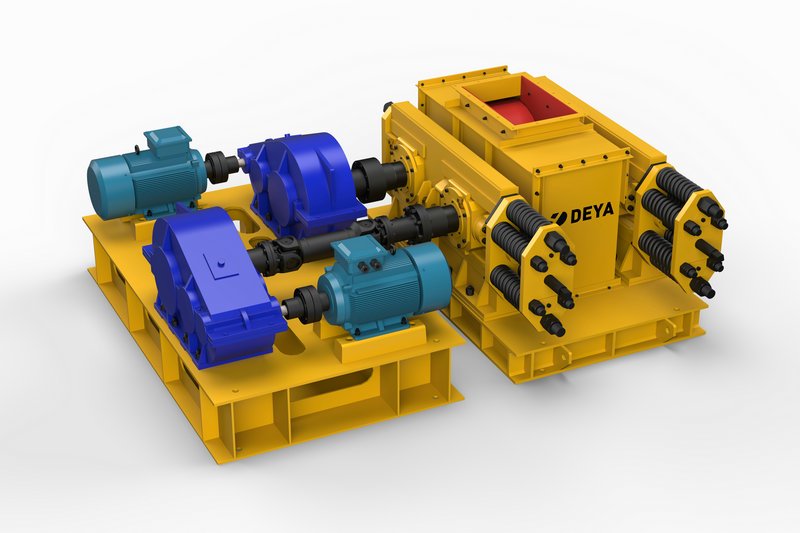

Double roll crushers are used for both, primary and secondary crushing. It consists of two or more adjacent rolls placed parallel to each other and rotated in opposite directions.

Mineral or rock particles placed between the rolls are nipped and then crushed as they pass between the rolls. Rolls are held against each other by springs.

Working principle

Material is fed by a continuous feed arrangement into the middle of the machine between both rolls.

The rolls operate at 5 m/s or even higher, and shear and compression forces crush the material between the roll in the gap. The crushed material is released through the crusher base frame onto a discharge conveyor.

The floating roll enables the crusher to release tramp metal and adjust the gap by the hydraulic supported gap setting system.

Features

● Automated gap adjustment

In case of overload incidents, the hydraulic system reacts by retracting one roll and letting tramp metal or overloading

material pass through the gap. This dramatically reduces the need for personnel to enter the crushing chamber, ensuring

greater operator safety and reducing downtime.

● Versatility

The Double Roll Crusher crushes a wide range of material types reaching compressive strengths of up to 150 MPa and higher. It is less sensitive to wet and sticky material and can take in larger feed sizes, making it the optimal primary crusher for soft and medium hard rocks.

● Direct and V-belt drive options

Depending on the requirements, Deya Machinery's Double Roll Crushers can be equipped with direct and with V-Belt drive options.

● Adaptable design

With years of experience in tooth design, we use the latest technologies to match teeth, liners and gap settings to your operation. This not only optimises throughput but also reduces downtime.

● High throughput rates and service life

Deya Machinery's Double Roll Crushers are capable of impressively high throughput rates, up to 400 tph, thanks to the customised tooth and liner design and optimised installed power and drive set-up.

Double smooth roll crusher technical data

Model | 2PG-400x250 | 2PG-600x400 | 2PG-750x500 | 2PG-900x900 | 2PG-1000x800 | 2PG-1200x800 | 2PG-1200x1000 |

Roll diameter(mm) | 400 | 600 | 750 | 900 | 1000 | 1200 | 1200 |

Roll length(mm) | 250 | 400 | 500 | 900 | 800 | 800 | 1000 |

Max feed size (mm) | 20-40 | 20-70 | 25-95 | 25-95 | 25-95 | 40-100 | 40-100 |

Discharge size(mm) | 2-8 | 3-30 | 3-40 | 3-40 | 3-40 | 4-40 | 4-40 |

Capacity(t/h) | 2-10 | 4-30 | 6-80 | 10-90 | 15-100 | 20-120 | 30-140 |

Motor(kw) | ≤15 | ≤37 | ≤45 | ≤75 | ≤90 | ≤110 | ≤110 |

Weight exclude motors(KG) | ≤1430 | ≤3600 | ≤7650 | ≤18400 | ≤25200 | ≤25900 | ≤51000 |

Double teeth roll crusher technical parameter

Model | 2PGC-370x1200 | 2PGC-400X630 | 2PGC-450X500 | 2PGC-550X1000 | 2PGC-600X750 | 2PGC-600X900 | 2PGC-800X400 |

Roll diameter(mm) | 370 | 400 | 450 | 550 | 600 | 600 | 800 |

Roll length(mm) | 1200 | 630 | 500 | 1000 | 750 | 900 | 400 |

Max feed size (mm) | 20-60 | 50-150 | 80-200 | 100-300 | 100-400 | 100-400 | 100-400 |

Discharge size(mm) | 3-25 | 5-50 | 5-80 | 5-100 | 5-100 | 5-100 | 5-100 |

Capacity(t/h) | 3-5 | 10-60 | 20-6- | 30-120 | 30-120 | 30-120 | 30-100 |

Motor(kw) | ≤18.5 | ≤15 | ≤15 | ≤45 | ≤30 | ≤45 | ≤30 |

Weight exclude motors(KG) | ≤1600 | ≤4000 | ≤3700 | ≤7100 | ≤7650 | ≤7950 | ≤8500 |

Model | 2PGC-900x900 | 2PGC-1000x760 | 2PGC-1000x1500 | 2PGC-1200x660 | 2PGC-1200x1500 | 2PGC-1250x1600 | 2PGC-1370x1900 |

Roll diameter(mm) | 900 | 1000 | 1000 | 1200 | 1200 | 1250 | 1370 |

Roll length(mm) | 900 | 760 | 1500 | 660 | 1500 | 1600 | 1900 |

Max feed size (mm) | 150-500 | 150-400 | 150-600 | 150-400 | 150-600 | 150-600 | 200-800 |

Discharge size(mm) | 5-150 | 5-150 | 5-200 | 5-120 | 10-200 | 10-200 | 10-250 |

Capacity(t/h) | 30-200 | 30-150 | 50-200 | 30-150 | 80-250 | 100-300 | 200-500 |

Motor(kw) | ≤75 | ≤110 | ≤132 | ≤110 | ≤150 | ≤150 | ≤440 |

Weight exclude motors(KG) | ≤18700 | ≤21200 | ≤35000 | ≤26500 | ≤56000 | ≤58000 | ≤108000 |

Note

1. The determination of production capacity is based on the following conditions.

a) compressive strength of crushed ore ≤ 120 MPa.

b) surface moisture ≤ 2%.

c) Ore density of 1.6 t/m3.

d) continuously and evenly feed over the full length of the roll.

2. The qualification rate of the discharge particle size should be ≥ 80%.

3. The specification series listed in the table can be adjusted and developed according to the market needs.

4. The same specification double roll crusher can form a series of products with different production capacity to meet the requirements of different users according to the standard discharge size range.