Sand making plant

Basic information

●Material, limestone mixed with clay

●Feeding capacity 120 tons per hour

●Product, crushed sand

●Crushing stage, primary crushing, secondary crushing, tertiary crushing

Sand making plant process in detail

1. Raw materials loading

Raw materials site about 1 KM to crushing working site. Raw materials are loaded to the dump truck by excavator, and move to the loading place. Dump truck discharge all materials to the hopper.

2. Grizzly feeder separation

Under the hopper there is a grizzly feeder, grizzly bar distance 100mm, larger than 100mm are sent to the primary jaw crusher for crushing, while under 100mm will be sent to join the materials discharge from primary jaw crusher.

3. Primary crushing

Primary jaw crusher by 24x36 inches, with C.S.S. (closed side setting) size 120 mm, crushing capacity up to 120 tons per hour.

Motor 75KW main shaft rotation speed 250 rpm. Discharge materials together with the under grizzly materials will be sent to secondary crushing.

4. Secondary crushing

Secondary crusher by two sets of jaw crushers 10x47 inches, which is specially for secondary crushing use, maximum feed size 8 inches, C.S.S. size 40mm, main shaft rotation speed 330 rpm, motor 37KW per set.

Two sets capacity reaches 120 tons per hour. Crushed materials will be sent to horizontal shaft impactor or HSI for sand making.

5. Tertiary crushing

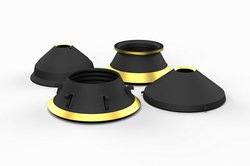

Tertiary crushing is by two sets of horizontal shaft impactor(HSI), it is designed and produced by Deya Machinery, with hydraulic opening device, easy for maintenance.

HSI with linear speed 50 meters per second, one set motor 160KW, very powerful and ideal equipment for limestone to produce sand.

Above the two HSI equipment is a hopper, and under the hopper there are two small vibrating feeders, it makes sure continuously and evenly feeding, so materials will be fed along the rotors, thus guarantees evenly wearing.

More than 70% crushed materials are less than 5mm, and 90% less than 10mm, 100% less than 16mm. Per set capacity up to 70 tons per hour, two sets guarantee capacity 120 tons per hour. Crushed materials are sent to vibrating screen for separation.

6. Screening and sand washing

Materials from two sets of horizontal shaft impactor are sent to a double layer vibrating screen, mesh size 10mm and 5mm.

Sand of 0-5mm are sent to a screw sand washer for washing, 5 to 10mm and above 10mm are sent to stockpile as end products.

Equipment are connected by belt conveyors.

Features

1. Large capacity with economical investment

2. Reasonable designing, three stages crushing reduce size step by step

3. Full service from A to Z, consulting, designing, quotation sheet, production, delivery, foundation making, installation, commissioning and training.

4. Complete plant with automatic running, PLC control panels with monitoring system.

5. Crushed sand are clean, and good cubic shape, sells at higher price

Contact Deya Machinery team to customize the sand making plant for you.

Photos of the equipment in delivery, installation and mass production