Sand washing plant

Basic information

●Material, river sand, white sand formed by volcanic ash

●Feeding capacity 150 tons per hour

●Product, washed sand

●Separation, sand washing

Sand washing plant process in details

1. Raw materials loading

Raw materials are river sand formed by volcanic ash, mostly are sand, with a few content of pebbles. Due to the multi-hole of volcanic pebbles, they are not strong enough in construction, they are separated as aggregate waste.

There is a large hopper installed under the solid concrete platform, raw materials are discharged from drum truck, directly to the hopper.

2. Feeding & washing on screen

Under the hopper a heavy duty apron feeder is installed for the feeding. It is ideally suited for feeding large, lumpy, abrasive and heavy materials during wet, sticky or frozen operations, speed will be controlled by frequency inverter control panel.

Slow and steady feeding guarantees the performance of vibrating screen.

Above the vibrating screen, high pressure water sprays are added. Washing on-screen is used to remove undesirable material, mostly clay and extremely fine particles.

It is also employed for the classification of fines or moist materials whose screening is very difficult without washing.

Washing is performed by applying water jets through spray nozzles directed as a water curtain and under pressure at the material being classified, aiming to remove the impure particles adhering to the material.

3. Screening and sand washing

Materials on the vibrating screen are classified by a two layer vibrating screen. The vibrating screen size 70x236 inches with two layers, first layer 10mm, second layer 5mm, it separates small pebbles.

More than 95% materials less than 10mm as aggregate waste. 5 to 10mm as product 1, and 0-5mm which will be further washed by screw sand washer as product 2.

For the 0-5mm, which account for about 70% of total materials are collected by a hopper and steel chute, by gravity and water slurry on the screen, they flow to the double screw sand washer.

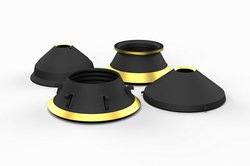

Screw washer is has a better efficiency because washing takes longer time. After washing, final clean sand is delivered to the stockpile.

Features

1. Large capacity with economical investment

2. Massive production, can work in two shifts per day

3. Heavy duty equipment, standard installation with maintenance corridors

4. Full service from A to Z, consulting, designing, quotation sheet, equipment production, delivery, foundation making, installation, commissioning and training.

5. Complete plant with automatic running, PLC control panels with monitoring system.

6. Washed white sand are cleaner, sells at higher price

Contact Deya Machinery team to customize the sand washing plant for you.

Photos from the client's working site