6x10 feet Ball mill 1830x3000

1. Technical data & general introduction

1.1 Technical data of ball mill 6x10 feet, close to China standard 1830x3000

Technical standard for ball mill: GB/T 25708-2010

Model: MQ1830x3000 (6x10 ft)

Rotation speed: 25.5 rpm

Grinding balls load: 12,670 kg

Maximum feed size: 25 mm

Discharge size: 0.074 to 0.3 mm

Capacity: 5.2 to 12.5 TPH

Mill shell thickness: 18 mm

Lining material: ZGMn13-4

Motor: YE3-355M2-8, 132 kW, 380 volts, three-phase, 50 hertz (or as required), work with frequency inverter control panel

1.2 Introduction of ball mill 6x10 feet

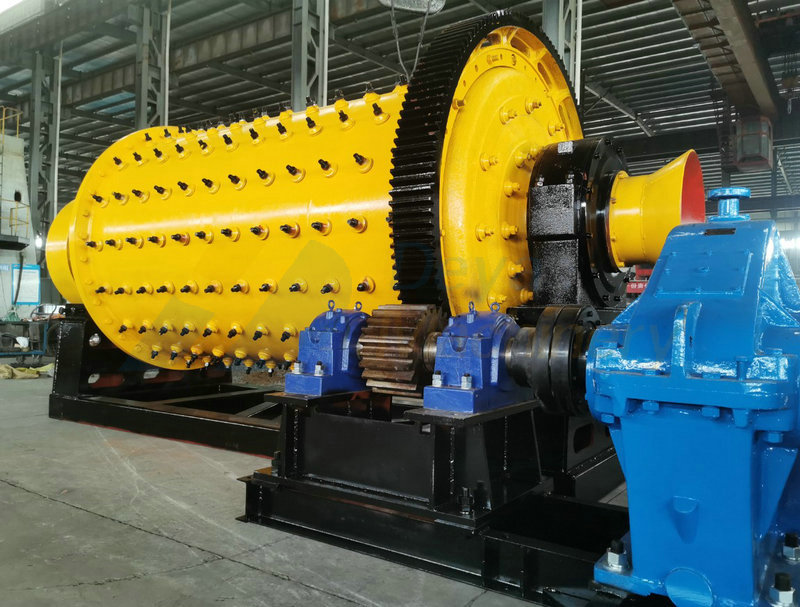

There are several key parts about ball mill, different brands of these key parts price will be great difference. Typically motor, gearbox, bearings, liners, frequency inverter(control panel). A complete ball mill 6x10 feet photo as follows

2. Assembly of transmission part

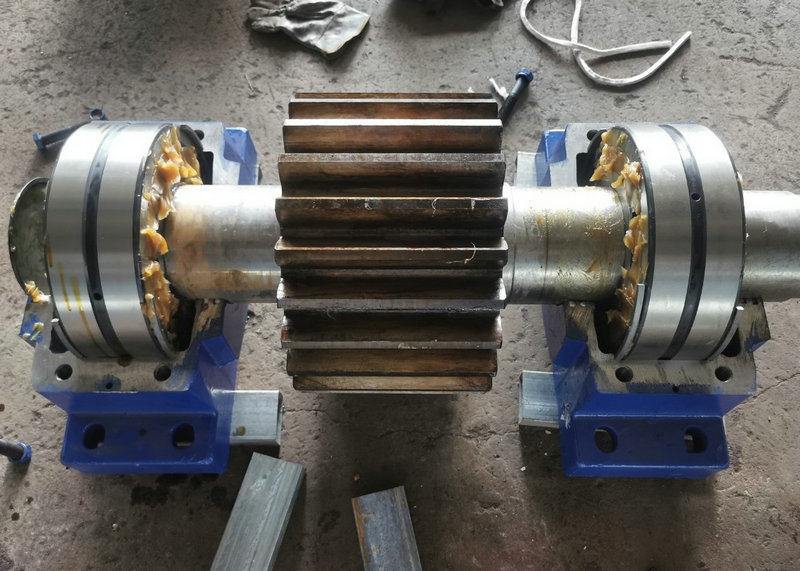

2.1 Installation of pinion, bearings, bearing seats and joint slack.

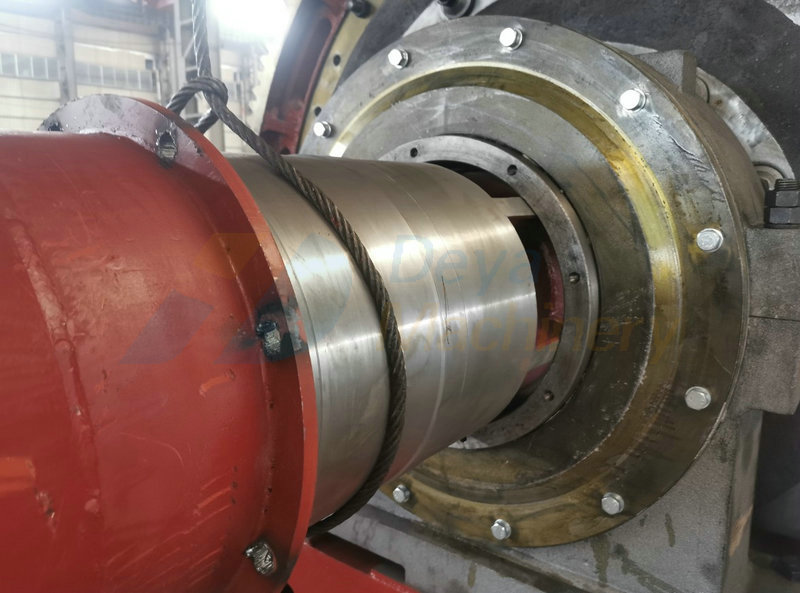

China top 3 brand bearings, original LYC brand

SNL3138 bearing seats, main shaft by forging with heat treatment and precise processing, interference fit installation of pinion

Add enough grease when install the bearings

Install joint slack on pinion side, interference fit

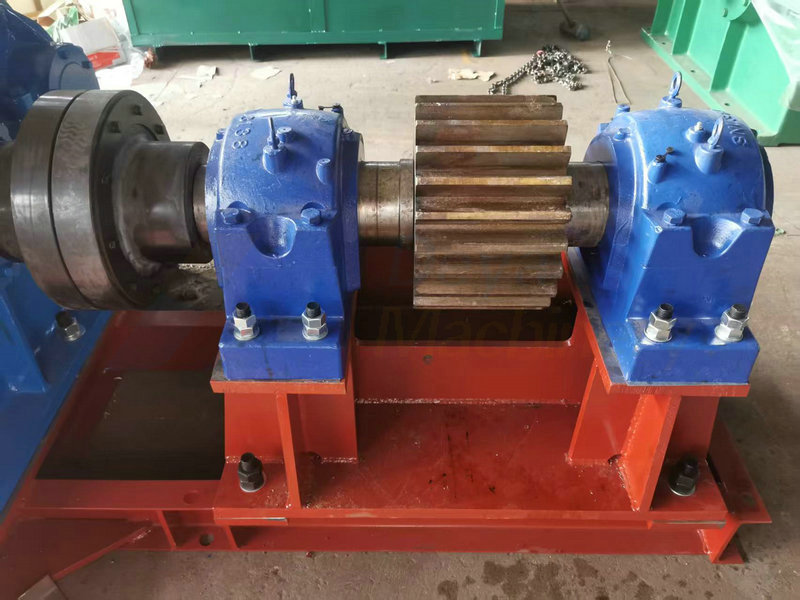

2.2 Base frame of the transmission part, key thing is same layer should be in perfect same level, the base frame should be processed on the lathe machine to guarantee smoothness on both sides.

2.3 Installation of motor, gearbox. Key thing make sure it is top brand motor and gearbox

3. Ball mill 6x10 feet drum shell, shell liners, mill heads, ring gear assembly

3.1 Ball mill drum shell should be well welded, after welding the flaw detection or crack detection should be tested, to guarantee the perfect welding joint. Flanges will be welded to the cylinder, then process on the Cylinder lathe to guarantee the perfection of circle.

3.2 Ring gear, mill heads, drum shell flanges assembly and drilling holes

3.3 Installation of shell liners, mill head liners. Key thing, high manganese steel liners ZGMn13-4 guarantees the lifetime.

Add sealing gum when install the mill heads

Manhole is important part, manhole liner with pine wood for backup

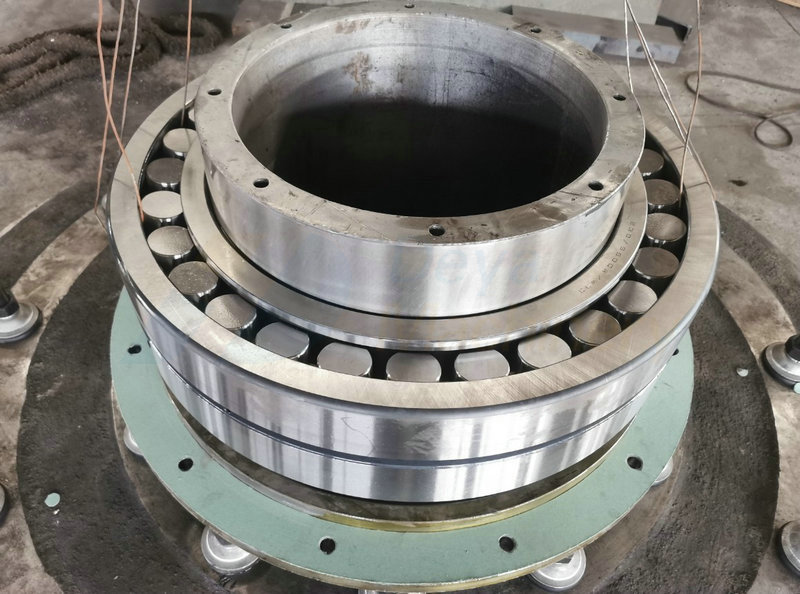

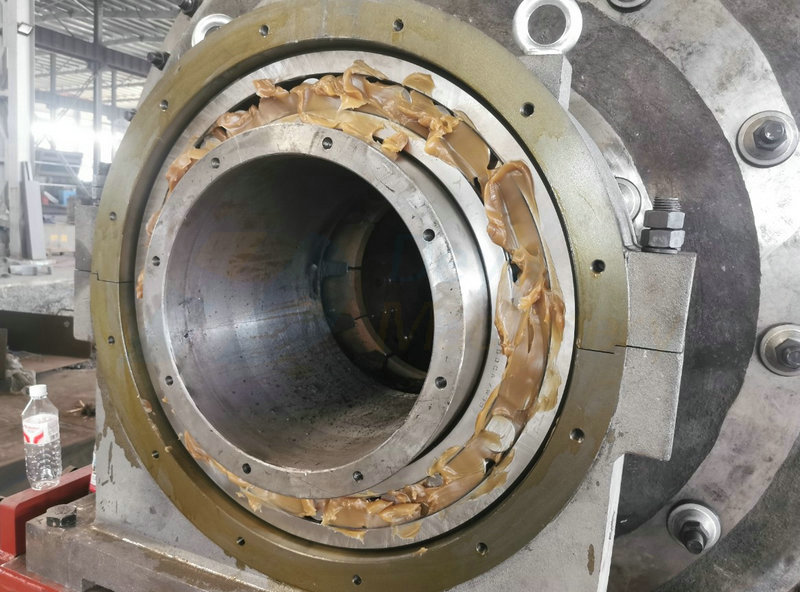

3.4 Installation of main bearings, bearing seats, sealings. Rubber pads should be added between sealings, add enough grease after bearings are installed.

3.5 Base frame of the ball mill. It is very important to make sure same layer both sides are on perfect level, the base frame should be processed on the lathe machine, to guarantee the smoothness and perfect level. Heavy duty base frame with 200 square hollow section(200mm SHS).

3.6 Installation of feeding and discharging unit, ring gear. Feeding and discharging units should be processed on lather machine to guarantee the smoothness.

4. Coat painting and surface painting, ready for the delivery

5. Ring gear safety guard, foundation parts, frequency inverter control panel

Deya machinery team puts heart and soul for each equipment supplied. Qualified equipment create much more value than expected, your trust value more than quality and service. Contact us for more information if you are interested.