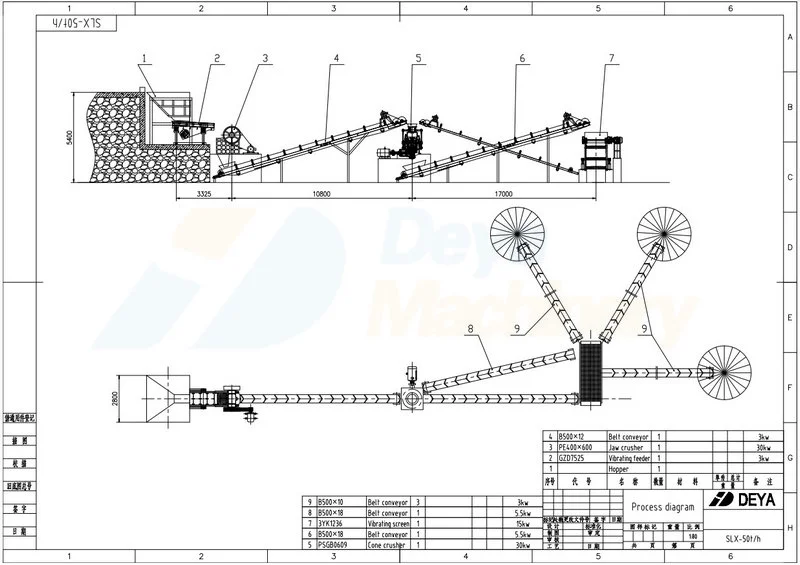

Stone crushing plant 40 to 50TPH

A standard stone crushing plant 40 to 50 tons per hour typically includes the following key equipment, vibrating feeder, primary jaw crusher, symons cone crusher, vibrating screen, belt conveyors, etc., the crushing plant is best known for hard stones like granite, basalt, river rocks crushing, it produces sand, 3/8'', 3/4'', and 1'', the crushed size can be customized according to requirements. Typical process diagram for 40 to 50 tons per hour crushing plant.

1. Vibrating feeder, materials feeding

Model: GZD2500x750, power 1.1KW x 2. Protection level IP54 or IP55.

Vibrating feeder is important to feed the primary crusher continuously and evenly. Please notice the two key points.

A. Use famous brand vibration motors, recommend Yutong or equivalent quality, best vibration brand in Henan province, also the most expensive one.

Use 6 pole vibration motor rather than 4 pole motor, because double vibration motors work in opposite direction, 4 pole with higher vibration, but when two works at the same time in opposite direction, it will be low vibration force. 6 pole motor is higher price than a 4 pole motor, it works well.

B. The feeder must be with wearable manganese steel liners

When loading the materials, the rocks will fall to the feeder directly, with protection liners, it will be more durable, also it is changeable after wearing.

2. Jaw crusher, primary crushing

Model: PE400x600(15.7x23.6 inches), motor YE3-225M-6-30KW. Eenergy efficiency rating YE3, protection level: IP55

Jaw crusher is for primary crushing, it reduces rocks from approximately 14 inches to less than 3 inches, crushing ratio 3 to 6. Please notice the four key points

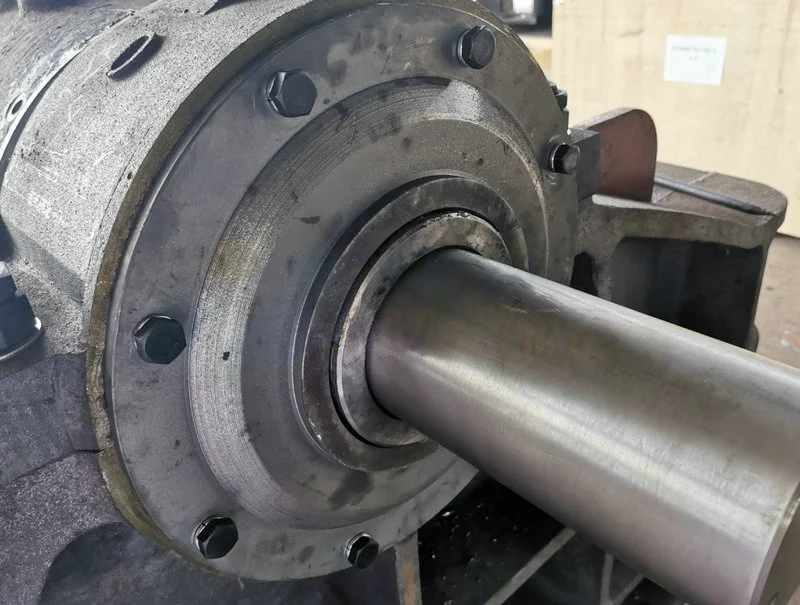

A. The main shaft must have heat treatment, or precisely thermal refining.

Normally the main shaft is forged part with embryonic form, next with rough processing, then thermal refining or heat treatment, finally fine processing to get qualified main shaft. Never choose a steel rod instead of forged main shaft, in case of hard stones, the main shaft produced by steel rod will probably break. While the forged one with heat treatment can handle any type of hard stones.

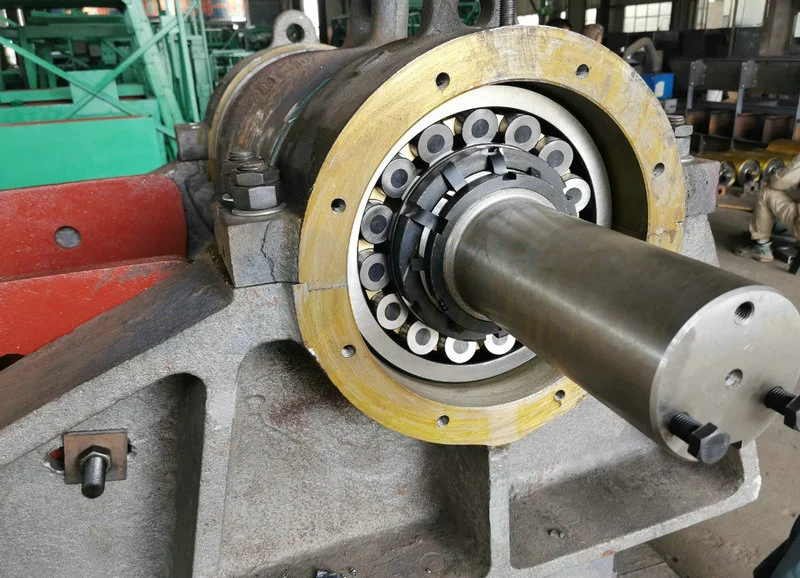

B. Bearings and correct assembly. Brand of bearings is important, low quality bearing may need replacement after one year or two, while top brand bearings with proper lubrication may use 5 years or even more. Bearings like LYC, ZWZ, these are top brands in China.

C. Correctly assembly is important, it make sure no error, and guarantees smoothly running. Deya Machinery experienced workers have more than 30 years of experience for the assembly. Attached photos in details.

D. Brand of motor, price have big difference, too. Top brand motor will be more stable running without problem, recommend Innomotics(former name Siemens Beide), Lu An, Wan Nan, Yutong, etc.

Important note: After jaw crusher assembly, test the equipment in 5 hours, non-stop. Check the sound and bearing temperature. In any case the bearing temperature can not exceed 70 ℃.

Deya Machinery's jaw crusher bearing temperature within 28 to 36 ℃ in 5 hours testing (workshop temperature 25 ℃), it is perfect running condition. Contact us to get the testing videos.

3. Symons cone crusher, secondary crushing

Model: PSGB0611, 2feet standard coarse, motor YE3-225M-6-30KW. Eenergy efficiency rating YE3, protection level: IP55

Key points similar like jaw crusher, empty testing minimum 8 hours non-stop.

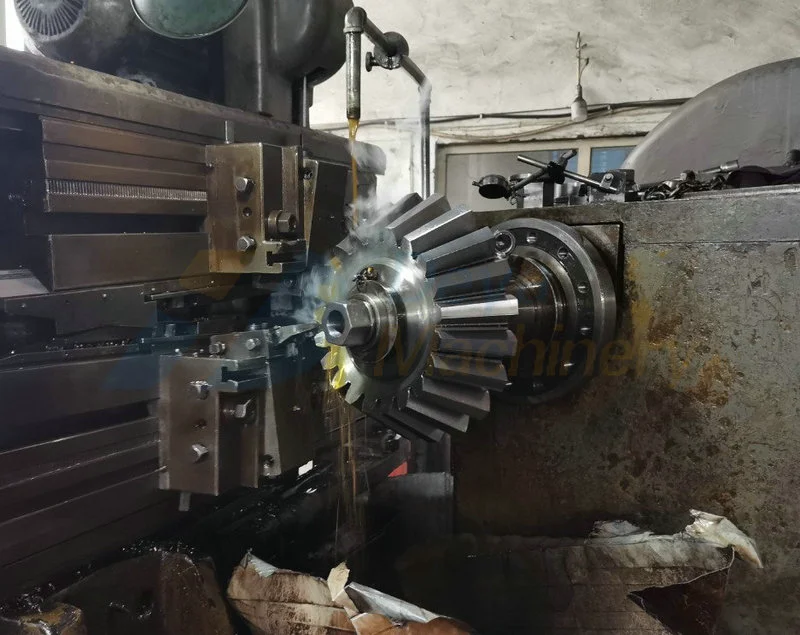

A. Main shaft must be forging parts with heat treatment.

B. Bearings need high quality, LYC, ZWZ are recommended brands.

C. Motor need high quality, Innomotics(former name Siemens Beide), Lu An, Wan Nan, Yutong are recommended brands.

D. Copper sleeve is an important part, recommend Dalian yongda, they produce best copper sleeve in China, for cone crusher use.

E. Umbrella type gears should be well processed

F. Correct assembly and 8 hours non-stop testing

G. Lubrication system, hydraulic system in high quality and well connection.

Always read Deya Machinery's symons cone crusher manual before the installation and trial run.

Important notice: lubrication system plays very important part for the stable running of symons cone crusher, the lubrication system should be started at least 5 minutes earlier before the main motor, and turned off 5 minutes after the main motor.

4. Vibrating screen, sand and gravel separation

Model: 3YK1236, or 4x12 ft, motor YE3-160L-6, 11KW. Eenergy efficiency rating YE3, protection level: IP55

Key points as follows, empty testing minimum 8 hours non-stop.

A. Non stop testing minimum 5 hours, bearing temperature no more than 50 ℃. Vibrating screen produced by Deya Machinery with empty testing, bearing temperature range from 28 to 37 ℃ (workshop temperature 25 ℃).

B. It is better to add polyurethane plates on the feeding and discharging places, this will guarantee less wearing on the screen.

C. High quality bearings are important to guarantee the stable running in several years. Recommend LYC, ZWZ bearings.

D. High quality motor is important as well, Innomotics(former name Siemens Beide), Lu An, Wan Nan, Yutong are recommended brands.

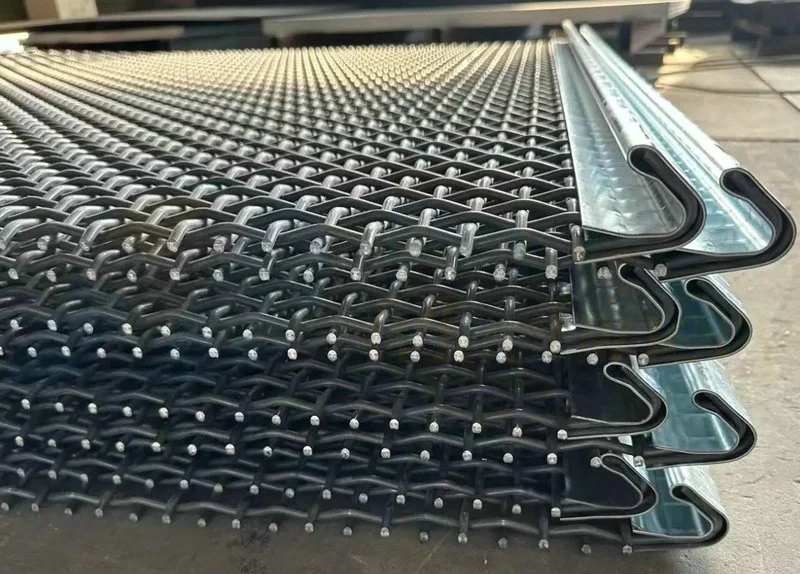

E. Screen mesh are wearing parts, recommend buying some additional for backup. Screen mesh should with steel wrapping, for easy replacement.

5. Belt conveyors, materials transporation between different equipment.

Belt conveyors are important for the connection of each equipment, also for the screened sand and gravel. Typical key points as follows:

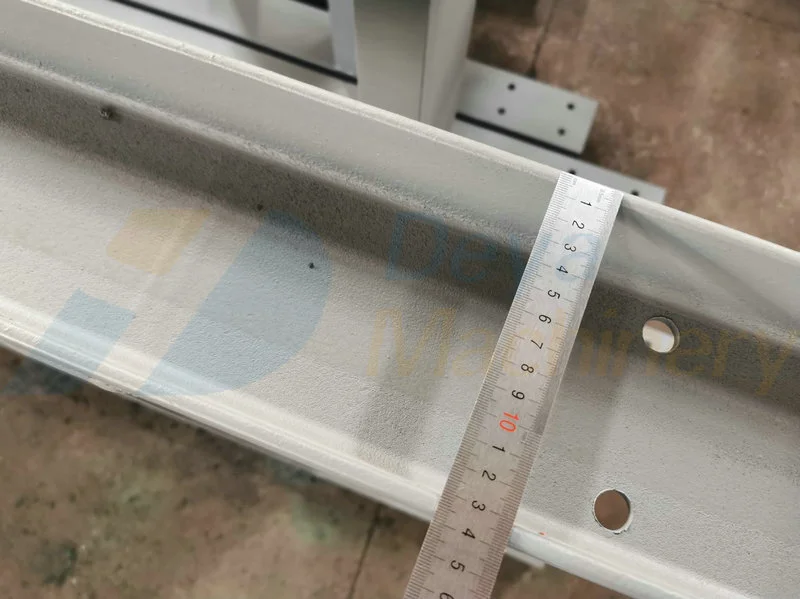

A. Main frame should use heavy duty U-steel, width 500mm and 650mm recommend minimum 120# U-steel, while width 800mm and 1000mm recommend minimum 140# U-steel.

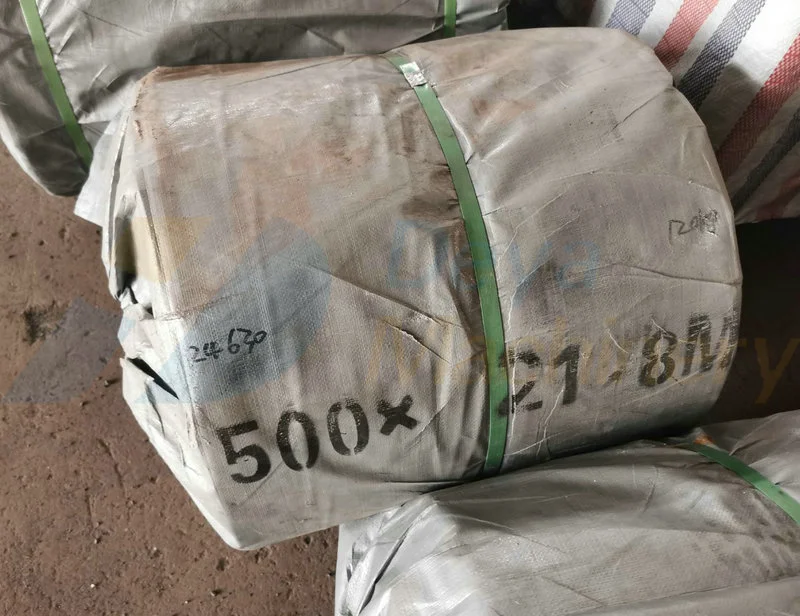

B. Rubber belts standard, recommend EP150. Conveyors length less than 30 meters EP 150 standards is good enough. Rubber thickness is not the most important thing. Top 3mm low 1.5mm with 4ply for width 500mm and 650mm, while for width 800mm and 1000mm, recommend minimum EP 150 with top 4mm low 1.5mm and 5 ply.

Keep in mind that rubber belt standard EP150 is important, if strictly produce with this standard, the rubber belts are good enough for the quarry plant use for several years without change.

C. Rubber belts better connection by glue rather than bucket fastener, connect the rubber belts in the installation site.

D. Rubber belts should be 1.8 or 2 meters longer than the conveying length. For example, if belt conveyor conveying length is 10 meters, the rubber belts should be 21.8 meters or 22meters.

E. Drive roll and idler roll, they should be made in heavy duty, so can be used for minimum 20 years. Attached photos for reference.

F. Conveying rollers and supporting rollers, buy the heavy duty type, it can be used for many years without change.

G. Drive motor and gearbox should be high quality, Innomotics(former name Siemens Beide), Lu An, Wan Nan, Yutong are recommended brands.

H. The drive gear and chain should be double, it is heavy duty. Attach photos in details.

6. Motor control panels

Key thing is use the famous brand parts for the motor control panel, like Chint brand, or Delixi brand. It is better with protection for all the motors, in case of sudden increase of the current, it will stop the motors to avoid further damage. This part is not produced by Deya Machinery, but we always buy the best brand for our clients.

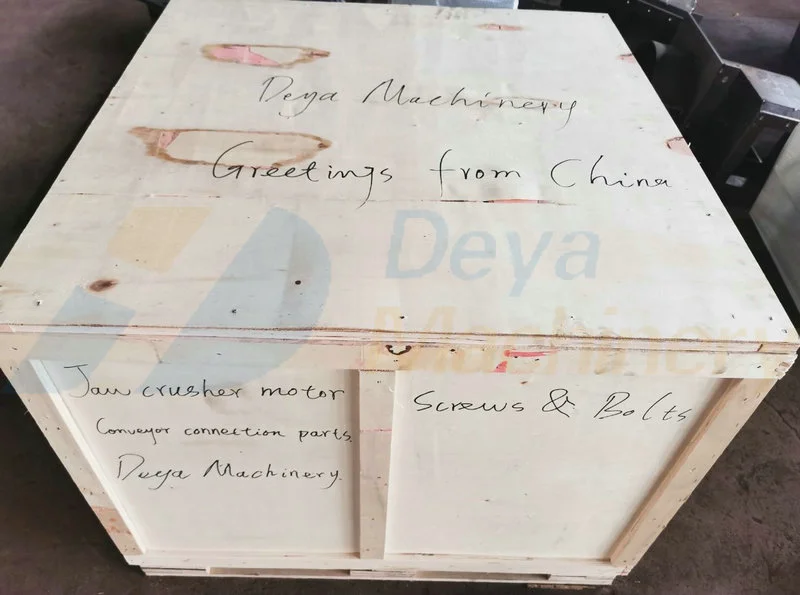

6. Package and delivery

Proper package is extremely important, it will avoid damage during the delivery. Key parts like motor, gearbox, it is better to be packed by wooden box, or steel case. Equipment must be fasten well inside the container.

Words beyond equipment

Deya Machinery is a great team, we guys really love this industry and firmly believe qualified equipment will create more value than expected, we are not a large company, but we are always doing great things with heart and soul. Contact us to customize the crushing plant for you, we are always grateful for choosing us as your business partner!