Introduction

Grizzly screen is used for fine-grained materials that do not need to pass through the primary crusher before crushing, reducing the burden on the primary crusher. It is an ideal equipment for processing raw materials with high content of fine-grained materials such as blasting rock, gravel and river pebbles.

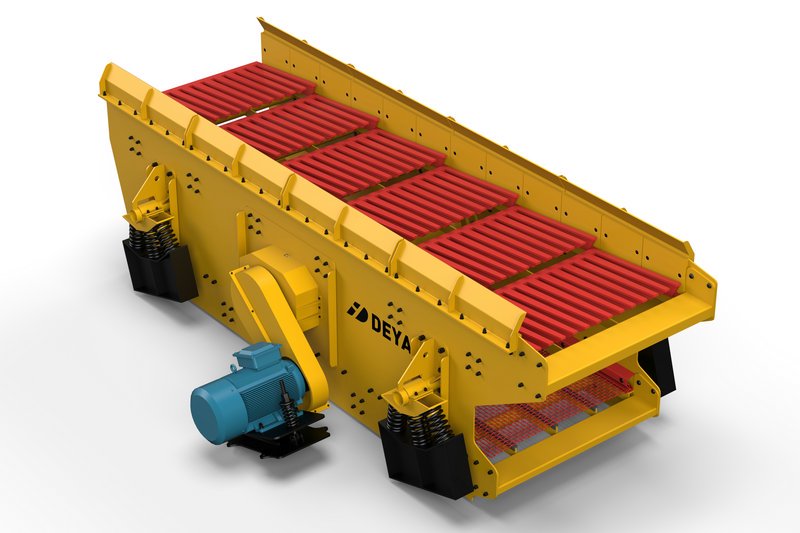

Grizzly screens are built with extra heavy duty applications by Deya Machinery. They are circular motion inclined screens with two decks or three decks, fitted with grizzly on the top deck, and wire mesh on the lower or bottom deck.

Application of grizzly screen

Grizzly screen is widely used in Household and Industrial Waste, Construction Waste, Electronic Scrap, Slag or Ash, Tires Recycling, Stone, Coal, Minerals, Ore, etc.

These screens are heavy and have more powerful motors and drives than a regular circular motion screen. They have been designed for river pebbles with pre-screening with a maximum feed size of up to 400 mm.

Deya Machinery Grizzly screens are robust, linear-motion screens designed for heavy-duty scalping, and the removal of fines from the feed before primary crushing.

The grizzly screens are built with a rugged, heavy-duty design for large feed and tonnages. These grizzly screens are

most commonly utilized in conjunction with an apron or pan feeder ahead of the primary crusher.

Grizzly screens are often utilized when excessive clay or an abundance of fines are present, making them capable of efficient scalping in the most difficult applications.

Grizzly screen features

• Bolted screen body

• Side plates with top and bottom flanges

• Top deck is fitted with two integral grizzly sections, featuring diverging gap between the bars

• The grizzly is made of wear-resisting steel, one piece for each grizzly section and bolts to the crossbeams

• Bottom deck designed for side-tensioned media. C-type clamps are used for bottom deck

• Bolted wear-resisting liners to protect the sidewalls at the top and bottom decks

• Discharge plate at the bottom deck

• Surface treatment according to Deya Machinery standard

• Easy installation & operation

Advantages

• Strong exciter generates a circular stroke that results in better feeding

• Versatile adjustment possibilities ensure optimum screening performance

• High acceleration keeps the grizzly section clean

• Eccentric shaft with spherical roller bearings

• Unbalanced flywheels with external counterweights

• The mechanism tube is protected by rubber liner

• Motor pulley, V-belts, sheave and pivoting motor base

• Transmission guard

• Flywheel guard

• Support brackets

• Coil springs

• Base mountings equipped with friction brakes

Structures & key parts

1. Cross Members

Heavy duty fabricated cross members absorb the impact of large feed and form the basis for the grizzly support deck.

2. Huck Bolt Assembly

The huck bolt assembly eliminates welding on the side plates and the problematic stress concentrations that can result.

3. Feed Plate

The feed plate absorbs the impact and extends grizzly bar life for reduced maintenance and down time.

4. Deep Section Grizzly Bars

Deep section grizzly bars allow up to 6’’ nominal spacing without interference from cross members. A variety of spacing options are available upon request.

Technical data of grizzly screen

| Model | Deck size | Inclination | Amplitude | Number of layer | Capacity | Power |

|---|---|---|---|---|---|---|

| mm | degree | mm | m³/h | Kw | ||

| 2YK1237 | 1200×3700 | 15-20 | 8-12 | 2 | 15-86 | 11 |

| 3YK1237 | 1500×3500 | 15-20 | 8-12 | 3 | 16-90 | 15 |

| 2YK1548 | 1500×4800 | 15-20 | 8-12 | 2 | 22.5-162 | 22 |

| 3YK1548 | 1500×4800 | 15-20 | 8-12 | 3 | 22.5-162 | 30 |

| 2YK1854 | 1800×5400 | 15-20 | 8-12 | 2 | 32-312 | 30 |

| 3YK1854 | 1800×5400 | 15-20 | 8-12 | 3 | 32-312 | 37 |

Note: These values correspond to material with bulk density 1,6 t/m3 and are recommended values only (i.e. other figures might occur in special applications/screen sizes).