Introduction

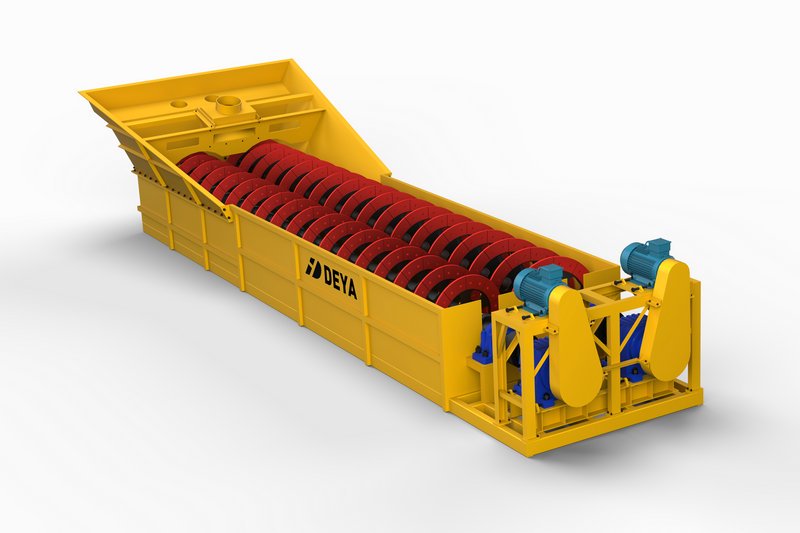

Screw washer is used for cleaning gravel and crushed stone containing clay or other contaminations. The screw washer uses a double shaft for a better efficiency in cleaning.

It uses the principle of different material particle size and density has different settling speed in the fluid, namely smaller particle size and density settling speed is slow, while larger particle size and density settling speed is faster.

This characteristics and principle separates dust and powder from the sand and gravels. Under the steadily rotation and stirring of spiral plates, it achieves the aim of removing impurities, filtering, lifting and conveying.

Working principle

The dirty mineral is fed in at the lower end of the trough which is mounted in an inclined position. The trough is inclined at about 7.5° to 14°.

The material is then transported to the upper trough discharge by the rotating spiral blade shafts working in opposite directions. The interacting blades create a lifting and friction action on the conveyed material. This movement causes friction between the stones and the screw blades. During this process clay will be washed from the material and dissolved in the water.

The dirt or clay dissolved in the water leaves the trough at the feed end water outlet, while the cleaned material is discharged at the upper end of the trough.

Construction of screw washer

• The screw washer produced by Deya Machinery with heavy and solid design. The trough is made of formed steel and

completely welded with bolted wear plates at the feed and discharge ends. This increases the machine lifetime.

• The machine is driven by two electric motors, V-belt drive and spur gears. The synchronous running of both blade shafts is achieved by a set of timed gears which are enclosed in an oil bath.

• The screw shafts have spherical roller bearings, which are mounted in generously dimensioned bearing housings.

• The screws are arranged in a spiral to avoid impacts or power peaks in the transmission system.

• To achieve a long lifetime of replaceable blades, which are made of special wear-resistant steel or polyurethane, shafts are run at low speed.

Characteristics

• Substantial trough design with wear plates at the face walls.

• Rigid screw shafts in heavy duty spherical roller bearings.

• Replaceable screws made of wear resistant steel or polyurethane.

• Individually replaceable shaft journals.

• Reliable gear reducers.

Technical data

| Model | FG-50 | FG-75 | FG-100 | FG-120 | FG-150 | FG-200 |

| Screw diameter(mm) | 500 | 750 | 1000 | 1200 | 1500 | 2000 |

| Screw rotation speed(r/min) | 18 | 16 | 13 | 10 | 8-10 | 6-10 |

| Capacity(T/H) | 3-20 | 5-40 | 10-70 | 20-90 | 30-130 | 40-200 |

| Power(KW) | 5.5 | 7.5 | 11 | 15 | 22 | 30 |

Note: According to different materials, feed size and other factors, the results will be different. Contact Deya team for more information.