Introduction

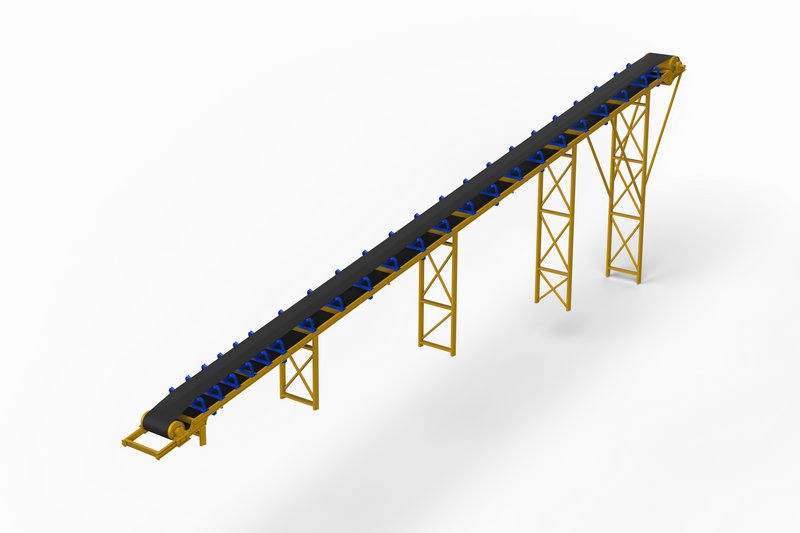

Belt conveyors are the most economical powered conveyor and are typically used for conveying products over long distances, at high speeds. It connects each equipment and makes the complete crushing plant runs automatically.

The belt conveyor is designed to transport material in a continuous movement on the upper part of the belt. The belt surfaces, upper on the carrying strand and lower on the return strand, touch a series of rollers that are mounted from the conveyor structure in a group known as a troughing set.

At either end of the conveyor the belt wraps around a pulley, one of which is coupled to a drive unit to transmit the motion.

Working principle

The rear end of a belt conveyor is known as tail-end and its forward end is known as head-end. The material is fed onto a belt conveyor at tail-end.

The material fed onto the belt conveyor rests on its upper run and travels forward with the belt. The material on reaching the head pulley drops down automatically due to gravity and discharge velocity, while turning round the head pulley.

Thus material is conveyed from the tail-end to the head-end in a continuous manner. The point where material is put on the belt is known as feed point or loading point.

The conveyor can have more than one feed point or moving feed point. The point where material is getting discharged from the belt is known as discharge point. Generally, this point is head-end of the conveyor.

Carrying idlers

1. Three in line idler rolls: the most commonly used, which consist of three in line idler rolls of equal length.

2. Impact idlers: to reduce the mass loading impact, thus to protect the belt.

3. Return idlers: for supporting the belt in return side, positioned between brackets attached directly to the conveyor frame, they carry the weight of the empty belt in the return side or the lower side of the conveyor.

Factors for belt conveyor capacities

Belt capacity is dependent upon these inter-related factors:

• Width of the belt

• Speed of the belt

• Material bulk density and surcharge angle

• Inclination angle

• Troughing angle

Rubber belt standard designation

Typical marks

EP400/3 500 5.0+1.5 200m DIN-X

• EP stands for Polyester(NN for Nylon)

• 400 for total tensile strength

• 3 for total ply

• 500 for belt width in mm

• 5.0 for top cover rubber thickness in mm

• 1.5 for bottom cover rubber thickness in mm

• 200m for belt length in meters

• DIN-X for rubber grade

Selection of conveyor belt

The conveyor belt is the most important element of a belt conveyor installation, it should be capable of doing the following tasks

• Transport the load.

• Absorb the impact energy at the loading point.

• Withstand temperature and chemical effects (heat, oil, acidity, etc.).

• Meet safety requirements (flame resistant, antistatic etc.)

Belt Cover Thickness

The top cover and bottom cover protect the carcass against weakening during service life of belt. The top cover is thicker compared to the bottom cover because operational strain and wear is much more in the top cover.

As a general rule, 80% of conveyor belt surface wear occurs on the top cover of the belt with approximately 20% of wear on the bottom cover.

Short belts (below 50 metres) usually wear at a faster rate because they pass the loading and discharge points more frequently compared to long belts.

The thicker cover, the better? Not necessarily, covers that are too thick can potentially cause other problems. It is recommended that the difference in thickness between the top cover and the bottom cover should not exceed a ratio of more than 3 to 1.

If the difference in the thicknesses between the covers is too great, the natural shrinkage of the rubber after being vulcanized can lead to harmful tensions in the belt.

Technical data for quarry plant conveyor

| Belt width | Transmission length (m) | Conveying speed | Capacity | ||

| mm | Power(KW) | m/s | T/H | ||

| 500 | ≤12 | 20-30 | 20-30 | 1.3-1.6 | 78-191 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| 650 | ≤12 | 12-20 | 20-30 | 1.3-1.6 | 131-323 |

| 4 | 5.5 | 7.5-11 | |||

| 800 | ≤6 | 6-15 | 15-30 | 1.3-1.6 | 278-546 |

| 4 | 5.5 | 7.5-15 | |||

| 1000 | ≤10 | 10-20 | 20-40 | 1.3-2.0 | 435-853 |

| 5.5 | 7.5-11 | 11-12 | |||

| 1200 | ≤10 | 10-20 | 20-40 | 1.3-2.0 | 655-1284 |

| 7.5 | 11 | 15-30 | |||

Note: Base on different materials, feed size, material abrasiveness and other factors, the data may be different. Contact Deya team for more information.