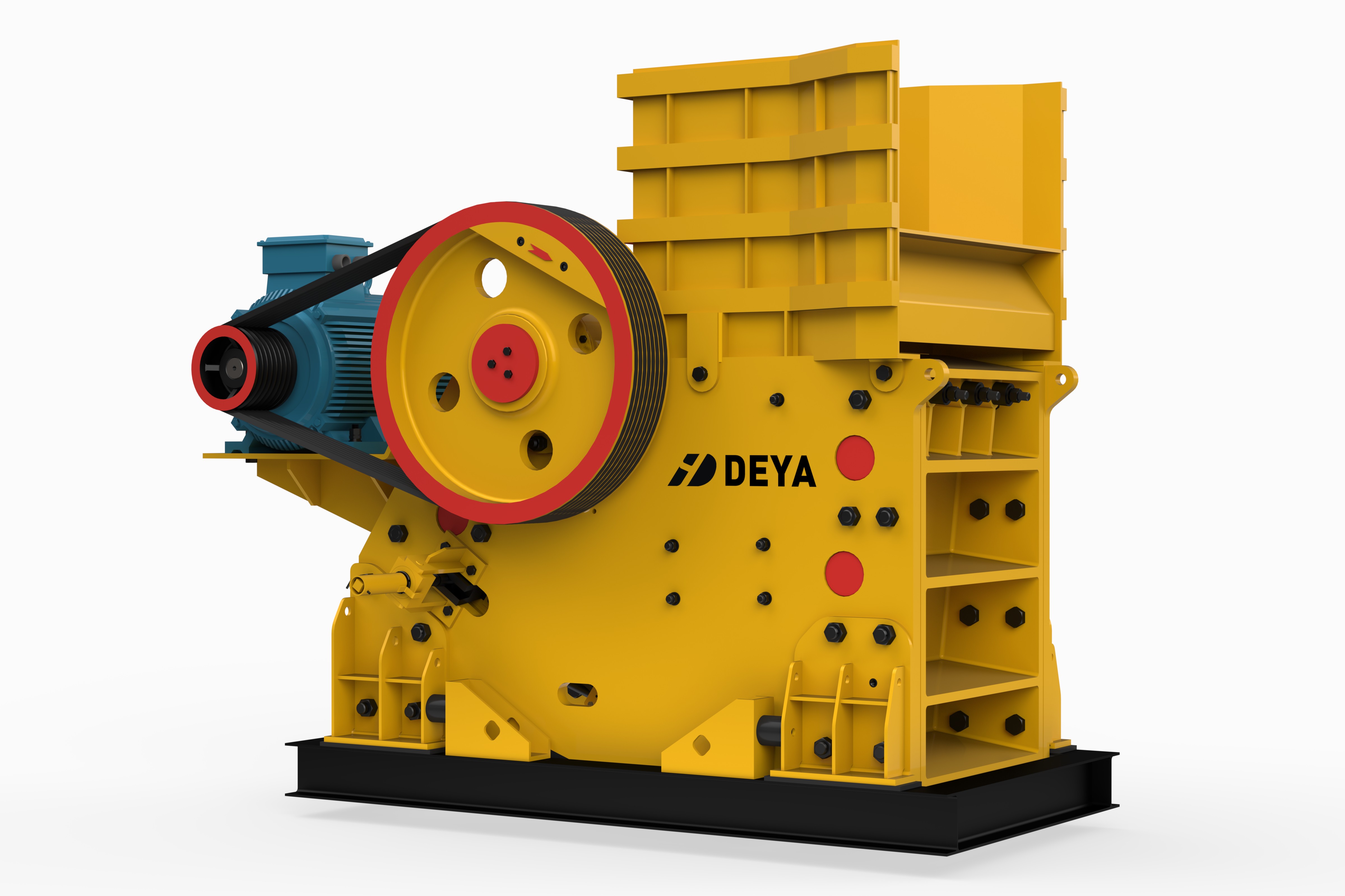

Introduction of Jaw crusher

Jaw crusher is widely used in mining, metallurgy, building materials, highway, railway, water conservancy area, it is mainly for crushing various ores and large materials to smaller sizes, breaking strength no more than 320 Mpa. PEF series jaw crusher is for primary crushing, while PEX series is for medium and fine crushing.

Features of Jaw crusher

1. The distinctive feature of jaw crusher is the two plates which open and shut like animal jaws. The jaws are set at an acute angle to each other, and one jaw is pivoted so that it swings relative to the other fixed jaw. Material fed into the jaws is alternately nipped and released to fall further into the crushing chamber. Eventually it falls from the discharge aperture.

2. According to the width of the feed opening, there are three types of jaw crushers: large machines with feed opening width greater than 600mm, medium machines with feed opening width 300-600mm and small machines with feed opening width less than 300mm. Jaw crusher is simple in structure, easy in manufacture and reliable in work.

3. Jaw Crusher is the traditional product in crushing and beneficiation plants, it is suitable for crushing a variety of soft and hard ores and rocks. PEF series are for primary crushing, while PEX series are for secondary crushing. Primary Jaw Crusher and Secondary Jaw Crusher are two main types.

Working principle of Jaw crusher

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates.

One jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker.

The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke.

The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

Technical data

| Model | Feed opening | Max feed size | C.S.S. range | Capacity | Rotation speed | Power | Weight | Overall size |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | T/H | RPM | Kw | Ton | mm | |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-20 | 300 | 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 150-200 | 80-240 | 275 | 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-180 | 250 | 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 130-190 | 130-330 | 250 | 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 160-220 | 150-336 | 250 | 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 200-260 | 190-336 | 250 | 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-290 | 230-390 | 250 | 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 180 | 160-220 | 100.9 | 4200×3300×3500 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 | 2720×1950×1600 |

Note: The crusher capacities listed are based on instantaneous sampling of medium hardness material. The above data are for reference only, please contact our engineers for equipment selection of specific projects.

The table of production capacity can be used as reference for the initial selection of jaw crushers. The data in the table applies to the production capacity of materials with a bulk density of 1.6t/m³, feeding materials smaller than the discharging particle size have been screening out, and under the open circuit operation conditions.

PEV jaw crusher introduction

PEV series jaw crusher is designed with unique V-shaped cavity, which is widely used in primary and secondary crushing of stones. It crushes various kinds of ore and river pebbles which crushing compression strength no more than 300Mpa, such as metal ores crushing, river pebbles crushing, construction waste crushing, cement plant raw materials crushing, etc.

It provides high quality of sand and gravel aggregates for the construction of highways, railways, bridges, hydro-power dam, concrete mixing stations and other industries.

Features

1. Excellent material intake capacity

Feed opening depth, which typically defines the top feed size, is well balanced with the width and height of the jaw crusher. A good feed opening depth enables excellent material intake capacity and ensures that the rocks enter the cavity without restrictions.

2. Super bite in the cavity

The steep nip angle, the angle between the movable and fixed jaw dies, ensures good bite and good material flow down in the crushing cavity. On top of the great performance, a good nip angle also reduces wear on the jaw plates, it has a direct impact on operating costs.

3. High production and reduction ratio

Deya PEV series jaw crushers are well known for the aggressive motion of the pitman and long stroke in the bottom of the cavity. The stroke is amplified from the top to the bottom, which means that the stoke is always longest in the bottom of the cavity. This boosts the capacity as well as the reduction ratio, resulting in high production and better end-product gradation.

4. Easy maintenance

Areas where any wear is anticipated are engineered to be easy to replace or protected by sacrificial wear items. This ensures that maintenance of PEV Series jaw crushers is easy and cost efficient over the long lifetime of the crusher. These designs protect the most expensive main components from wear and shorten maintenance time. And a shorter maintenance time means higher uptime.

PEV jaw crusher technical data

| Model | PEV500×750 | PEV600×900 | PEV700×1060 | PEV950×1250 | PEV1200×1600 | |

| Feed opening(mm) | 500×750 | 600×900 | 700×1060 | 950x1250 | 1200x1600 | |

| Power(KW) | 55-75 | 90 | 110 | 160 | 250 | |

| Weight(KG) | 8000 | 11000 | 22000 | 41000 | 81500 | |

| Product size (mm) | C.S.S. size (mm) | t/h | t/h | t/h | t/h | t/h |

| 0—60 | 40 | 55—80 | ※ | ※ | ※ | ※ |

| 0—75 | 50 | 70—90 | ※ | ※ | ※ | ※ |

| 0—90 | 60 | 80—110 | 90—125 | ※ | ※ | ※ |

| 0—105 | 70 | 105—130 | 110—150 | 125—180 | ※ | ※ |

| 0—120 | 80 | 120—150 | 140—180 | 165—200 | ※ | ※ |

| 0—135 | 90 | 130—170 | 155—200 | 185—230 | ※ | ※ |

| 0—150 | 100 | 150—190 | 180—250 | 210—270 | 250—320 | ※ |

| 0—185 | 125 | 190—220 | 215—280 | 250—300 | 300—360 | ※ |

| 0—225 | 150 | 200—260 | 230—290 | 265—335 | 320—400 | 420—555 |

| 0—260 | 175 | ※ | 250—315 | 300—350 | 380—460 | 495—665 |

| 0—300 | 200 | ※ | ※ | 320—400 | 410—590 | 575—690 |

| 0—340 | 225 | ※ | ※ | ※ | 560—650 | 650—775 |

| 0—375 | 250 | ※ | ※ | ※ | 600—715 | 725—870 |

| 0—410 | 275 | ※ | ※ | ※ | ※ | 800—970 |

| 0—450 | 300 | ※ | ※ | ※ | ※ | 880—975 |

Note: The above data marking crusher´s theoretical capacity aims at the phenomenon that material bulk density is 1.6t/m³, feeding evenly,outputting smoothly and no blocking. The capacity is also related to containing mud and water of material, crush ability, etc. Contact Deya Machinery to recommend right equipment and customize the crushing plant for you.