Introduction

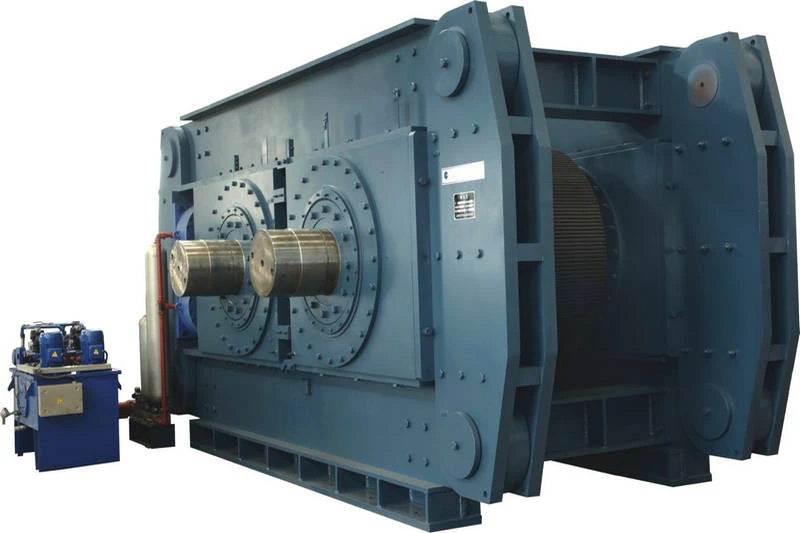

The machine is centered around two counter rotating rolls. They are supported in the frame by spherical roll bearings, which are inherently self-aligning and very robust.

One of the machine rolls, called the fixed roll, is supported directly on the press frame, whilst the other roll called foating roll is supported in the frame by a hydro-pneumatic spring system that allows for horizontal movement of the roll during operation.

This movement of the foating roll constitutes the basic principle of high-pressure comminution with a roll press. The extent of the roll movement is a function of the pressing force generated by the hydraulic system in relation to the reaction forces exerted by the processed material.

With this design feature, it guarantees that, during the comminution process, all the feed material passes through the roll gap under the same process conditions, thus ensuring that the HPGR output quality remains constant.

The compression is achieved by applying high pressure of up to nearly 300Mpa, exceeding the compressive strength of the feed material. During this process, the material is ground to a wide particle size distribution with a large proportion of fines, compacted into flakes.

Features

• Superior machine design, ensuring process reliability and ease of maintenance

• Highly developed wear protection systems providing long service life and steady operation

• Control systems to monitor, adjust and optimize the comminution process

Benefits

• Low energy consumption (0.8–2.2kWh/t)

• Enhanced downstream mineral recovery

• Improved downstream grindability

• Substantial savings from reduced grinding media consumption

• Improved productivity and recovery

• Compact frame design for lowest civil cost

• Optimal product quality via controlled roll skewing and self-adjusting lateral walls

Working principles

HPGR is pressure controlled, not gap controlled

• Product size is changed by controlling the pressure

• Size reduction by inter-particle grinding

• Inter-particle grinding increases grinding efficiency as pressure is transferred to the particle via multiple directions

• Breaking and fracturing of particles only happens when the material compressive strength is exceeded

• Pressure controlled HPGR assures that the right pressure is applied for the specific material

• Accepting larger feed size than ball mills and producing finer size particles than cone crushers.

Technical data

| Series | Model | Roll diameter (mm) | Roll width (mm) | Feed size (mm) | Capacity (T/H) |

|---|---|---|---|---|---|

| 10 Series | GM 100/30 | 1000 | 300 | ≤40 | 50-100 |

| 10 Series | GM 100/40 | 1000 | 400 | ≤40 | 80-140 |

| 12 Series | GM 120/40 | 1200 | 400 | ≤50 | 100-200 |

| 12 Series | GM 120/80 | 1200 | 800 | ≤50 | 150-400 |

| 15 Series | GM 150/50 | 1500 | 500 | ≤60 | 150-350 |

| 15 Series | GM 150/80 | 1500 | 800 | ≤60 | 350-500 |

| 15 Series | GM 150/120 | 1500 | 1200 | ≤60 | 400-800 |

| 17 Series | GM 170/60 | 1700 | 600 | ≤65 | 250-550 |

| 17 Series | GM 170/120 | 1700 | 1200 | ≤65 | 500-1100 |

| 17 Series | GM 170/150 | 1700 | 1500 | ≤65 | 700-1400 |

| 20 Series | GM 200/80 | 2000 | 800 | ≤70 | 400-850 |

| 20 Series | GM 200/120 | 2000 | 1200 | ≤70 | 600-1300 |

| 20 Series | GM 200/160 | 2000 | 1600 | ≤70 | 900-2000 |