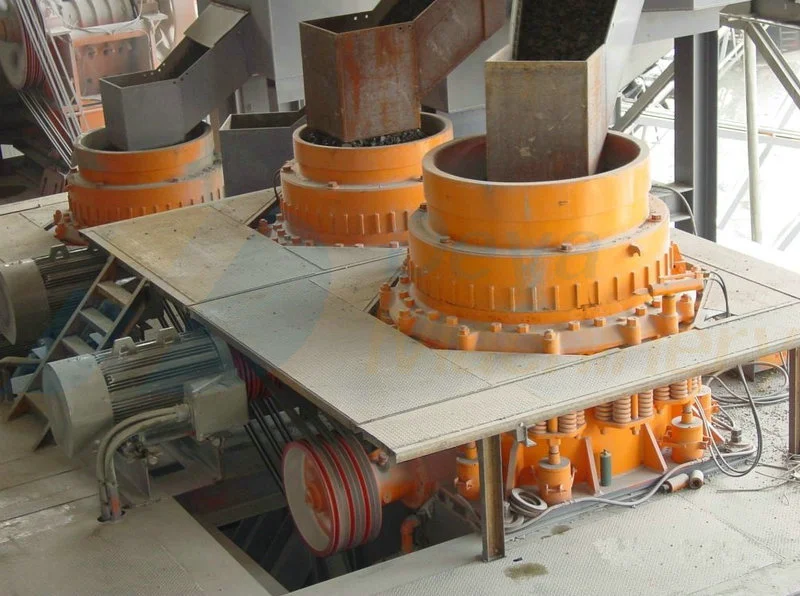

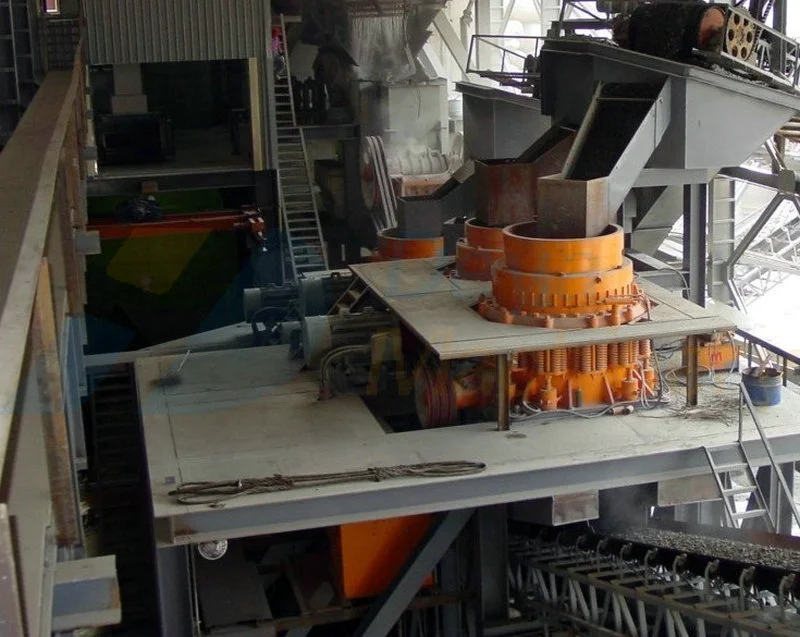

Lubrication system in a Symons cone crusher

Lubrication system introduction

Lubrication system is very important part for the symons cone crusher. In a typical symons cone crusher lubrication system, the working principle is as follows:

The oil under pressure is forced upward and downward between the bearing surfaces of the main shaft and inner eccentric bushing and bearing surfaces of the eccentric assembly where the oil spills onto the gear and pinion teeth.

At the same time the oil is forced upward through a drilled passage in the main shaft where an angular drilled hole through the mantle core directs the oil to the veering surface of the spherical seat liner.

The overflow of oil from the concave bearing surface is drained of through holes in the spherical seat onto the fear teeth.

The oil, which drains off the fear teeth, collects in a sump at the under side of the main frame where drain piping directs the oil back to the tank.

A pressure switch, temperature switch and flow switch can be installed in the lubricating oil system to provide automatic safety devices which when energized will either stop the symons cone crusher or give audible warning of an abnormal condition.

Lubrication system specifications

Use a high grade paraffin base industrial oil of viscosity specified, having high film strength, having high affinity for and adhesiveness to metal surfaces, having stable chemical and physical properties.

Such lubricants should have a high viscosity index, rapid water separation, resist foaming, offer some rust and corrosion protection, resist oxidation and have anti-wear additives.

For normal, all year operating conditions, corresponding to oil temperatures leaving the crusher at below 60℃, but preferably above 27℃.

Oil specification for lubrication system

Use the GB5903-1995 that supply by market, the industry closed gear oil which the viscosity grade according L-CKD 100 of GB3141, viscosity index≥90.

Correct lubricants meeting the above specifications are essential for the protection of the working parts of the symons cone crushers. They are available from all major oil companies.

Improper lubricants can ruin the symons cone crusher and their use will void any warranties pertaining to such crushers.

Oil temperature

The oil temperature of symons cone crusher should keep in the range of 38-54℃ and it would be best in the range of 38-46℃. The symons cone crusher is not allowed to work when the oil temperature above 60℃ or under 16℃.

A higher oil temperature will guarantee the lubricating oil proper functioning and keep the character.

Cooling device should be used if the ambient temperature or working condition make the oil temperature of symons cone crusher reach to 46℃.

Also the electric heater should be used in cold weather or oil temperature in the tank is under 16℃.

Key components in the lubrication system

Oil tank

The oil tank is a simple, efficient reservoir for furnishing oil to the symons cone crusher lubricating system.

Oil returning to the oil tank from the symons cone crusher drain line passes through a wire mesh which removes any particles of foreign matter, 10 mesh or larger.

Then flowing under and over a baffle arrangement for maximum setting of sludge, the oil enters the feed line to the oil pump.

Oil pump of the lubrication system

The independently driven pump system is preferred in most symons cone crusher installations as it permits lubrication before starting the symons cone crusher and is a more flexible and better controlled system.

The oil pump capacity, pipe line sizes and bypass relief valve size have been selected and set to provide the symons cone crusher with an ample supply of lubricating oil and to insure cooler operation.

Oil filter

An oil filter is supplied when finer filtration of the lubricating oil is desired, than can be obtained from the 10 wire mesh screen in the oil tank, thereby giving additional life to the symons cone crusher bearing parts.

Filters with varying degrees of filtration are available in either the replaceable, throw-away cartridge type, or the manually cleanable type.

As filters differ in size, construction and performance, reference should be made to the filter manufacturers instruction bulletin for installation and servicing.

Pressure switch

A pressure switch can be provided to protect the crusher in the event of oil pressure failure.

Should the pressure in the oil feed line drop below the minimum safe operating pressure of the symons cone crusher, the pressure switch is activated.

An electrical warning signal or machinery shut-down interlocking arrangement connected to the pressure switch, warns the operator against such pressure loss.

Temperature switch

A temperature switch installed in the oil drain line can serve to do either of two function. One is to be used as a high temperature alarm, the other is to operate a radiator type oil cooler fan motor automatically if the crusher has this type of oil cooler.

Should both the high temperature alarm and oil cooler operation be desired, two temperature switches would have to be used.

The temperature switch should be mounted in the drain line as near the oil tank as possible.

Flow switch

A flow switch can be installed in the system to protect against possible oil pump failure, oil line breakage or excessive oil leakage.

The flow switch will activate upon no oil flow. An electrical warning signal or machinery shut down interlocking arrangement connected to the switch warns the operator against such loss of oil flow.

Loss of flow can be caused by several conditions; Clogged or blocked drain or feed line, broken pipe or pipe firings or leakage within the symons cone crusher itself. A careful inspection will disclose the trouble.

Air cooler of the lubrication system

An air cooler, which is a large radiator similar to an auto-mobile radiator, through which the warm oil to the symons cone crusher is circulated, is easy to install, since it is practically ready for operation when received.

Piping to the radiator should be externally supported and no hung on the radiator itself. Flexible hose connections are recommended when piping to the radiator. The radiator should be installed between the oil pump and the symons cone crusher.

Never mount the radiator in an enclosed room as the air cooler depends on a continuing supply of moving air to cool the oil sufficiently.

Since mounted on the radiator is a large diameter motor driven fan that forces the surrounding air past the radiator core, fins and cools the oil, check the tightness of the fan motor hold down bolts.

At least once a year, drain the oil from within the radiator and clean the radiator tubes thoroughly with either a fiber or wire brush.

General instructions

• Insert the heater to the oil box by the pipe joint.

• Coat the sealants or put on the seal belt in the thread.

• Twist the heater to the pipe joints with wrench.

• Don't bend heating elements.

• Protect the heater terminals from wind and rain.

Note: All electrical wiring should comply with local electrical code. Pay attention to the rated voltage of the heater when wiring.

Lubrication system in operation

To make symons cone crusher and lubrication system normal work, adjust the oil station temperature within the range of 21-27℃.

• The electric heater will be self-turn-on and began to work when the oil temperature is below 21 ℃. The electric heater will be shut off automatically when the oil temperature is up to 27 ℃.

• Use the oil level indicator on the oil box side to observe the oil level and ensure at least part of oil heater buried in the oil.

This is very important because the exposure part of outside of the oil heating element will be burn out prematurely.

• The sediments of heater elements can’t be too thick and otherwise the heater will be burn out.

• Cut off the heater power supply when oil drainage from the oil box.

Regular inspections and maintenance is important to prolong the symons cone crusher, operate the equipment under Deya Machinery’s guide and operation manual. Contact us anytime when you meet a problem.