Impact crusher or symons cone crusher?

Introduction

Generally speaking, the major differences between an impact crusher and a symons cone crushers is the type of crushing force.

Impact crushers crush by material impacting another object. Symons cone crushers use compression crushing where the material is crushed by being squeezed or compressed between two crushing surfaces.

Selection of the type of crusher and the crushing process for any application depends on material hardness, and density of the material, feed size, desired product size, and capacity needs; as well as initial costs for each crusher and the cost to maintain each style of crusher.

Basic construction and working principle

Impact crusher normally consists of a hopper, two or three aprons, a rotor, and blow bars or hammers.

Essentially, large products are fed into the hopper where they come into contact with hammers or blow bars to a spinning rotor which crushes the material into smaller pieces.

As the larger material gets impacted by the hammers, it comes into contact with each apron rebounding it back to the rotating hammers for another round of impacting until it is discharged out of the impact crusher.

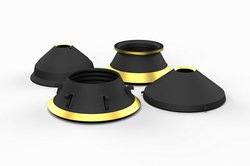

Symons cone crusher consists of a bowl liner, a mantle, both main shaft and frame, compression, and an eccentric inner and outer bearing.

Essentially, material is reduced in size by squeezing the material until it breaks.

Specifically, the material is compressed between a moving piece of steel, the mantle, and a stationary piece of steel, the bowl liner.

The final product’s size is determined by the closed-side gap setting between the two crushing members at the bottom.

As the cone eccentrically rotates, the material is crushed and works its way down through the crushing chamber, until it discharges at the bottom of the machine.

Material composition for the crushing process

In order to understand impact crusher and symons cone crusher processes, one must know the material that will be crushed, which will determine the optimal crusher for your business needs.

When considering the material to be crushed, you must look at abrasiveness, hardness, density, amount of fines, and the finished particle shape you desire.

Impact Crushers are used to crush softer, less dense and abrasive material such as limestone.

Because of its consistent striking process, an impact crusher produces uniform cubical finished products, which are desirable for hot asphalt producers.

Depending on the application, impact crushers can have higher wear costs, higher maintenance, and produce more fines.

Impact crushers may be used as a primary, secondary, or tertiary crusher depending on the producer’s final-product-size needs.

Symons cone crushers are primarily used to crush harder, more abrasive and dense material, such as granite, which is used in construction, chemical, metallurgical and silicate industries.

Symons cone crushers can be used in the primary, secondary, and tertiary crushing stage.

Overall costs

Impact crushers, initially, are less expensive than symons cone crushers. Although symons cone crushers are more expensive up front, they will require far less maintenance than impact crushers.

The majority of maintenance costs on an impact crusher comes from wear on the blow bars and aprons which if used to crush highly abrasive material, may surpass the initial cost of the symons cone crusher.

As stated earlier, producers must understand their industry needs and the materials they will mine in order to choose the optimal crusher.

Contact us for more information if you have trouble for choosing a crushing equipment.