6x12ft ball mill 1830x3600

1. Technical data

Ball mill technical standard: GB/T 25708-2010

Model: MQ1830x3600

Rotational speed: 25.5 r/min

Ball load: about 16000 kg

Maximum feed size: 25 mm

Discharge size: 0.074 to 0.3 mm

Capacity: 5.2 to 14 TPH

Mill shell thickness: 22 mm

Liner material: ZGMn13Cr2

Motor: YE3-355L-8, 132kW, 440V60HZ, three-phase, 60 Hz

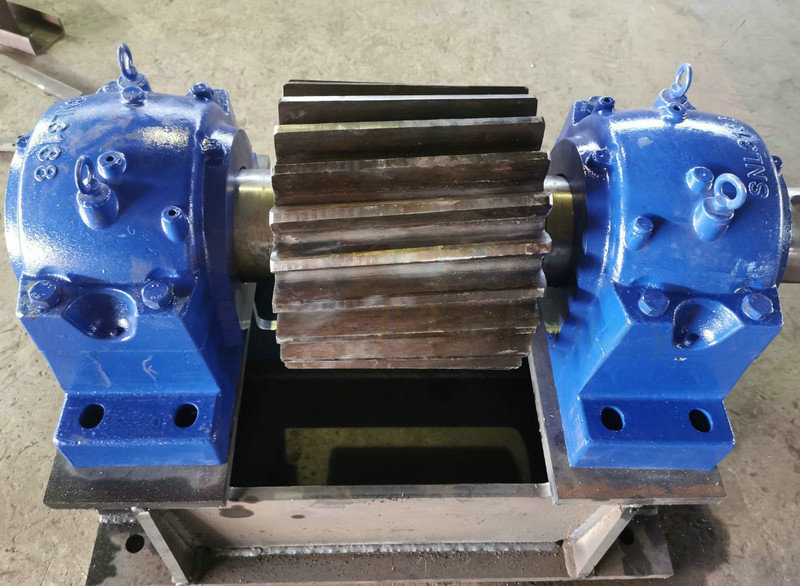

Gearbox: ZD60-4.5-Ⅱ

Frequency inverter(185KW) control panel included

Helical ring gear and pinion

2. Production procedure

Fabricated from steel plate, the shell and heads are typically an integrated welded unit designed for high impact, with machined trunnion flanges for precise alignment.

Ball mill heads and trunnion checking before assembly

Ball mill shell welding, after welding flaw detection or crack detection should be done, to guarantee the perfect welding joint

Ball mill processing on the horizontal lathe, it is a key heavy-duty machining process, mainly involving the precision machining of the mill heads trunnion and outer diameter of the shaft shell. High-precision rotational accuracy is achieved through this horizontal lathe.

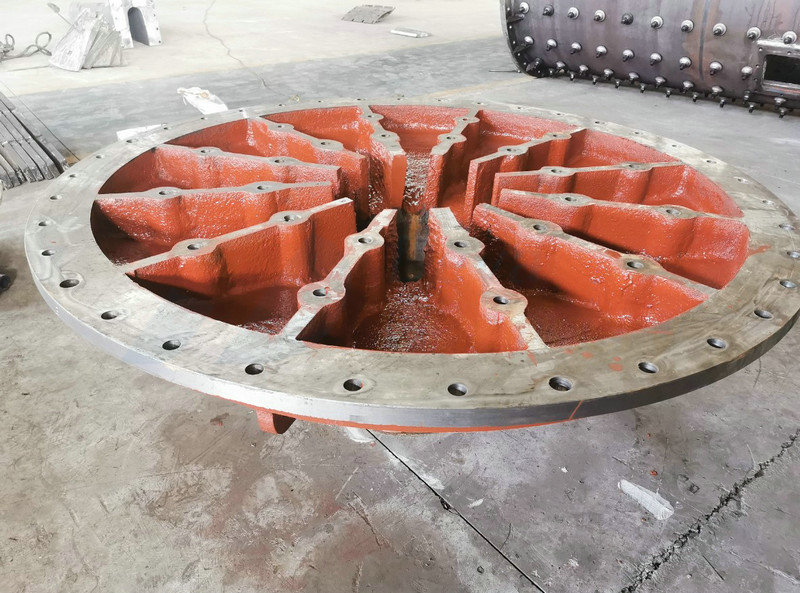

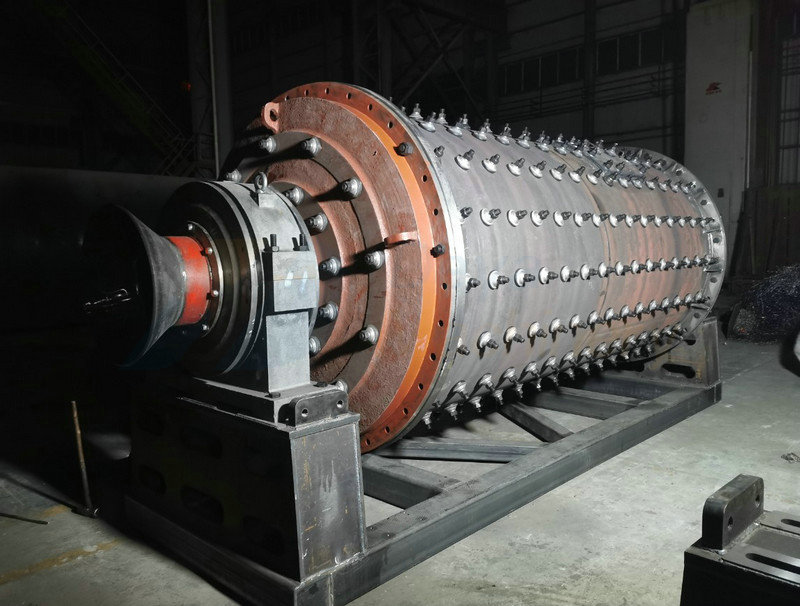

Ball flange and heads are assembled, then drilling holes to ensure connection accuracy

Installation of ball mill head liners

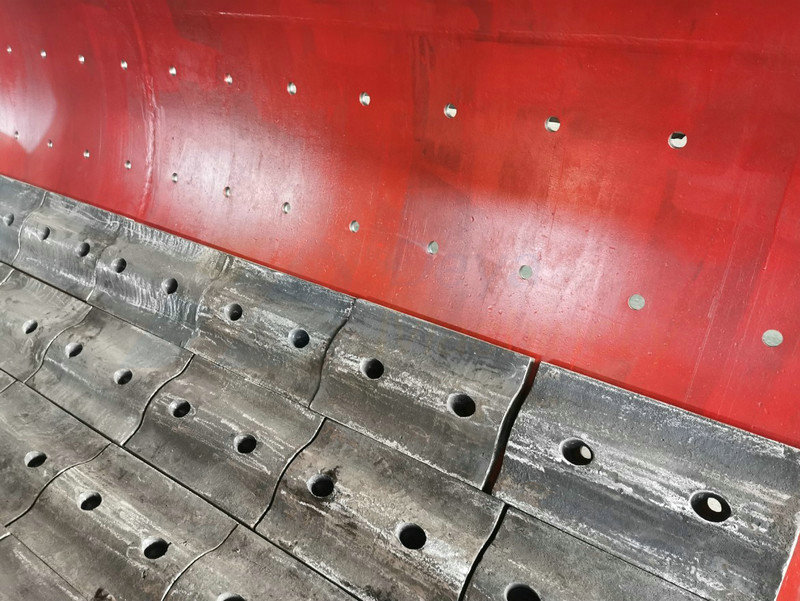

Installation of the shell liners

Manhole is important, pine wood plate for backup to make sure all the liners are in the same level

Thickness of the ball mill heads liners, shell liners, material: ZGMn13Cr2

Helical ring gear and pinion

Assembly of transmission part, China top brand motor, Gearbox

Transmission shaft by forging part with precise processing

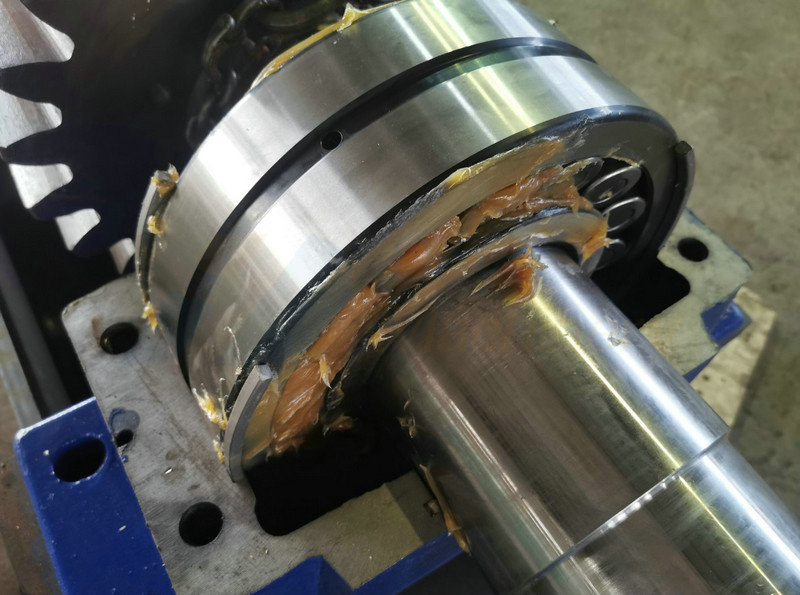

LYC bearings, add enough grease during assembly

Adjust shaft joints to perfect same level

Transmission part base processed on the lathe, installation layer in perfect same level

Heavy duty base frame process on the lathe, to guarantee both sides are in perfect same level

Ball mill feeding and discharging units, process on the lathe to guarantee the smoothness

Main bearings LYC brand, assembly of mill heads, add special glue during assembly

Add grease on the main bearings

Installation of bearing seats

3. Painting & package

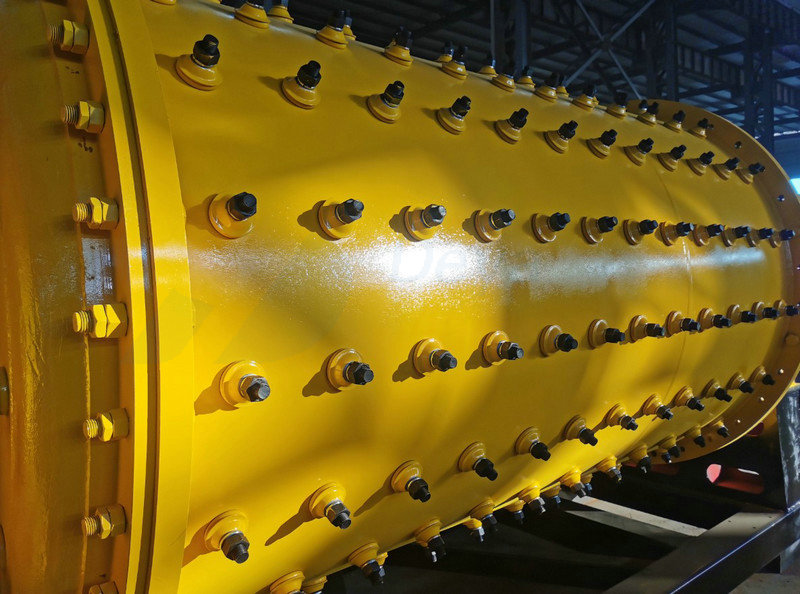

Ready to make painting, make cover for the bolts

Coat painting and surface painting

Foundation bolts and angle plates in wooden package

Frequency inverter motor control panel, 185 KW frequency inverter for motor 132KW, China top brand frequency inverter Ao Sheng brand

Due to the width of container, ring gear is separated before delivery

Ring gear safety guards

Marks on the ball mill head and ring gear, for easy and fast assembly

4. Delivery from Deya Machinery's workshop

5. Load to 40ft high container with secure fastening