Introduction

VSI sand making machine is mainly used for sand making in construction, it is the advanced equipment for producing artificial sand, which is specially designed to provide high quality sand and aggregate for the construction of highway, high-speed railroad, high-rise building, municipal, hydropower dam and concrete mixing plant, and it is also the shaping equipment in the field of artificial sand making and aggregate plant.

Usually it is worked with vibrating feeder, stone crusher, vibrating screen, sand washer, crusher, etc. to form a more economically and efficiently sand making line.

VSI sand making machine investment is 35% to 50% lower than the same scale of traditional process equipment, but output efficiency is 35% to 50% higher than the same scale of traditional process equipment.

For example, limestone with a finished product size ≤ 5mm accounted for more than 90%, river pebbles a finished product size ≤5mm accounted for more than 80%.

Long-term operation and maintenance cost is 35% to 50% lower than the same scale of traditional process equipment, it is widely used in the mechanism of sand and stone materials, cement, resistant materials, metallurgy and other industries.

Applications of VSI sand making machine

1. Artificial sand making of river pebbles, mountain stones (limestone, granite, basalt,etc.), ore tailings and stone chips.

2. Production of construction aggregate, highway road fabric, bedding material, asphalt concrete and cement concrete aggregate.

3. Production of artificial sand and products shaping for water conservancy and hydropower, high-grade highway, expressway, high-speed railroad, passenger line, bridge, airport runway, municipal engineering and high-rise building in the engineering field.

4. Fine crushing process in the pre-mill section of mining industry, material crushing in building materials, metallurgy, chemical industry, mining, refractory materials, cement, abrasives and other industries.

5. High abrasive and secondary disintegration crushing, desulfurization in thermal power and metallurgical industries, steel slag, construction waste crushing and other environmental protection projects.

6. Production of glass, quartz sand and other high purity materials.

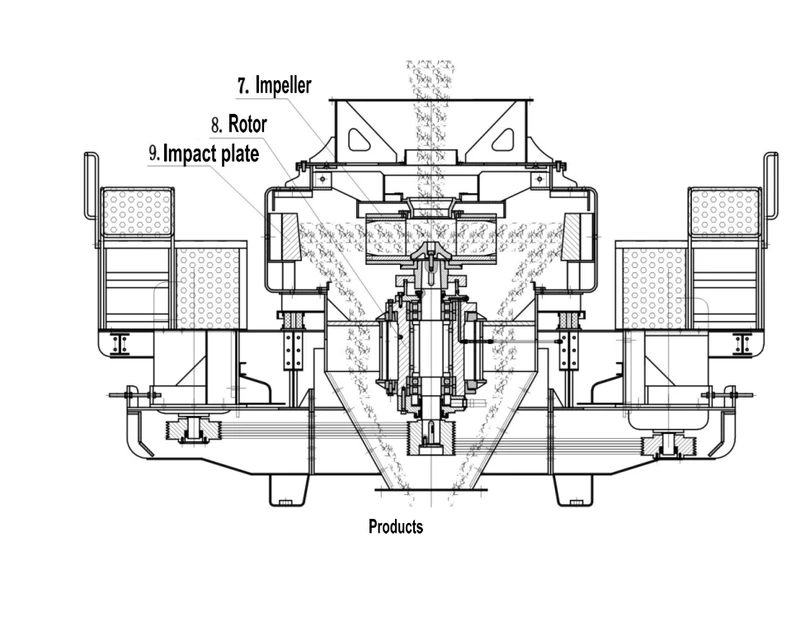

Working principle

VSI sand making machine is by the use of high-speed rotation of the materials to crush each other and the material between the friction and crushing (stone to stone), the maximum feeding size must be in accordance with the technical performance parameters of the machine, larger than allowed size materials are strictly prohibited to feed the machine.

The maximum water content of the sand making machine is less than 20%. Generally, the gravels coming out of the sand washer can be sent to the machine directly for crushing.

The discharge size of VSI sand making machine is related to the physical properties of the stones and the feed size, when the stones are fragile, the smaller the feed size, the higher rate of the qualified product size.

Conversely, the lower. The product size can also be adjusted by change the impeller speed. When the product size of the sand making machine is not larger than 10mm, the qualified rate is 60-90%.

In order to ensure the qualified rate of product size reaches 100%, it is necessary to use multi-stages crushing equipment in a closed circuit.

Features of VSI sand making machine

1. High processing capacity and high output, from 50 to 500t/h, compared with the traditional equipment under the same power, the output is increased by 30%, and the production is stable.

2. Low consumption of wearing parts, the optimized design of impact angle in the crushing cavity, makes it less friction with wear parts, it is about 30% lower than the traditional equipment operating costs, which directly reduces the operation costs of the equipment.

3. Excellent products shape, the product is in cubic shape, with reasonable gradation and adjustable fineness modulus; it is especially suitable for artificial sand making and stone shaping, which is proved to be 30% more effective than other traditional equipment for sand making and shaping.

4. Hydraulic device, easy to maintain, the machine with hydraulic cover opening device, so that the internal parts of the crushing cavity is easy to repair and remove, shortening the downtime, saving time and effort.

5. Automatic detection, safe and reliable, there is over-vibration display and alarm device, if there is abnormal operation it will alarm the warning and stop the machine for the purpose of protection.

6. Thin oil lubrication, automatic maintenance, original famous brand thin oil lubrication station, double oil pump complementary to ensure oil supply, it will be shutdown automatically if there is no oil flow, or no oil pressure.

There is oil cooling and heating device to ensure that the bearing lubrication is always in the best condition.

Thus completely solving the problems of bearing heating, keeping the spindle bearing at a constant temperature and extending the maintenance cycle and service life.

7. Easy installation and operation, equipment with light weight and a variety of installation methods, like mobile installation; The installation, repair and maintenance is simple, easy to operate and use.

Once the specific purpose is clear, VSI sand making machine can maximize its excellent performance by minor adjustments.

Technical data

| Model | Impeller diameter | Max feed | Passing capacity | Main shaft rotation speed | Motor | Overall size |

|---|---|---|---|---|---|---|

| mm | mm | T/h | RPM | KW | mm | |

| VSI 1570 | 1500 | ≤60 | 580-700 | 900-1000 | ≤2×400 | 6200×4100×3040 |

| VSI 1263 | 1150 | ≤55 | 430-490 | 1000-1150 | ≤2×315 | 5700×2965×3400 |

| VSI 1145 | 1030 | ≤50 | 350-430 | 1300-1390 | ≤2×220 | 5500×2730×3315 |

| VSI 9532 | 900 | ≤45 | 270-380 | 1500-1600 | ≤2×160 | 4800×2520×2920 |

Note: Base on different materials, feed size, material abrasiveness and other factors, the data may be different. Contact Deya team for more information.

The table of production capacity can be used as reference for the initial selection of impact crushers. The data in the table applies to the production capacity of materials with a bulk density of 1.6t/m³, feeding materials smaller than the discharging particle size have been screening out, and under the open circuit operation conditions.

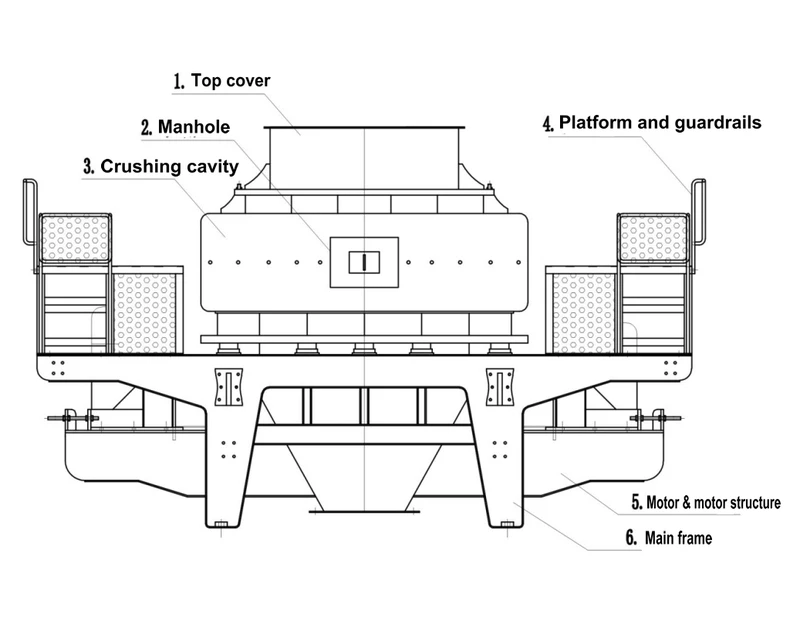

VSI sand making machine structures